The Best 3D Printer Laser Engraver: A Comprehensive Guide

Laser engraving has become an indispensable tool in modern manufacturing, offering precision and versatility for a wide range of applications. If you’re looking for the best laser engraving machine, particularly one that integrates seamlessly with 3D printing technology, this guide will walk you through everything you need to know. Whether you’re a hobbyist, a small business owner, or a professional in the manufacturing sector, understanding the features, benefits, and technical specifications of a high-quality laser engraver can help you make an informed decision.

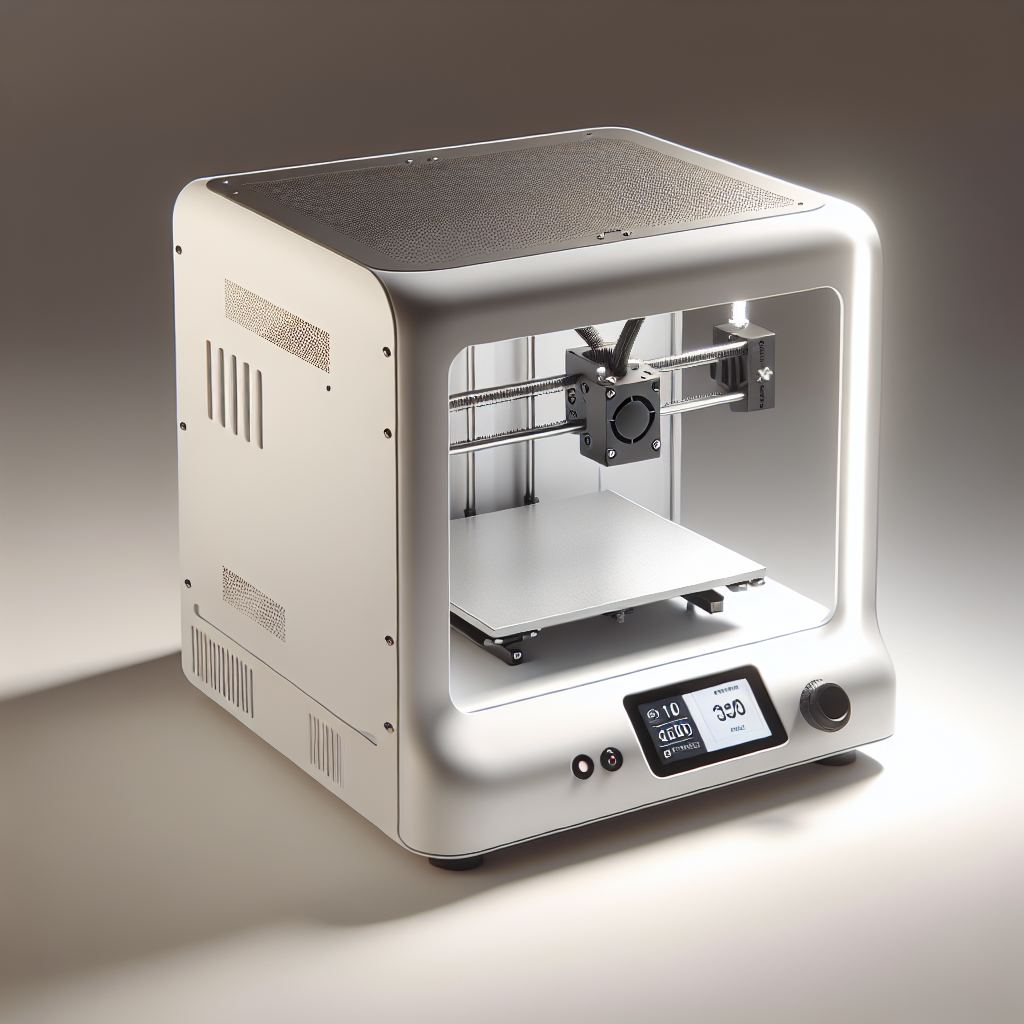

What Is a 3D Printer Laser Engraver?

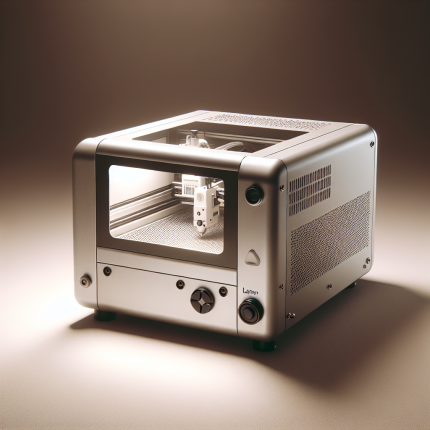

A laser engraving machine is a device that uses focused light beams to etch or cut materials with exceptional precision. When combined with 3D printing technology, these machines allow users to create intricate designs, patterns, and text on a variety of surfaces, including metals, plastics, wood, and glass. The integration of laser engraving with 3D printing opens up endless possibilities for customizations, prototyping, and small-scale production runs.

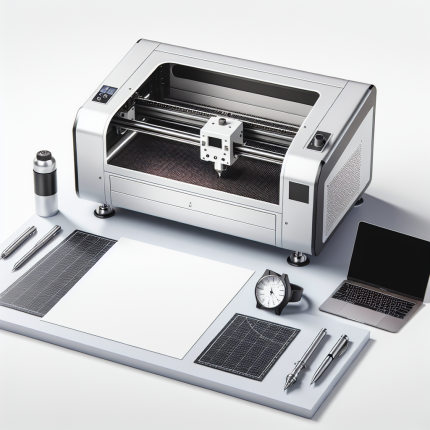

Key Features of the Best Laser Engraving Machines

When searching for the best laser engraving machine, there are several features to consider:

- Precision and Accuracy: High-quality machines offer micron-level precision, ensuring that even the most detailed designs are executed flawlessly.

- Versatility: Look for a machine that supports multiple materials and file formats, allowing you to work on different projects without limitations.

- Ease of Use: User-friendly interfaces and intuitive software simplify the engraving process, making it accessible even for beginners.

- Speed and Efficiency: Advanced machines are equipped with high-powered lasers and optimized software algorithms to reduce processing time.

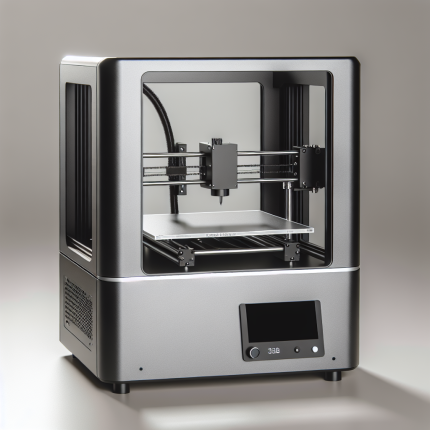

Technical Specifications

Here’s a breakdown of the technical specifications you should look for in the best laser engraving machine:

- Laser Type: CO2, fiber, or UV lasers are commonly used, each offering different advantages depending on the material being engraved.

- Power Output: Higher wattage lasers deliver faster and deeper engravings but may require more advanced safety precautions.

- Repetition Rate: This determines how quickly the laser can move across the surface, affecting both speed and precision.

- Working Area: The size of the engraving bed is crucial for handling larger projects.

- Build Quality: Sturdy frames and high-quality optics ensure durability and long-term performance.

Applications of a 3D Printer Laser Engraver

The versatility of laser engravers makes them suitable for a wide range of applications:

- Custom Design Work: Create personalized jewelry, nameplates, or promotional items with intricate details.

- Prototyping: Quickly produce prototypes for testing and validation in product development.

- Industrial Use: Apply serial numbers, QR codes, or branding elements on large-scale production lines.

- Artistic Expression: Use laser engraving to create unique art pieces, wall decorations, or sculptures.

How to Choose the Best Laser Engraving Machine

Selecting the right laser engraving machine involves considering several factors:

1. Material Compatibility

Different materials require different types of lasers. For example, CO2 lasers are ideal for non-metallic materials like wood and plastic, while fiber lasers excel at cutting through metals. Ensure the machine you choose is compatible with the materials you plan to work with most frequently.

2. Budget

Laser engraving machines vary widely in price, depending on their features, power output, and intended use. Determine your budget early on to narrow down your options and focus on models that offer the best value for money.

3. Maintenance and Support

Investigate the availability of spare parts, software updates, and customer support. A reliable manufacturer will provide comprehensive after-sales service to keep your machine running smoothly.

4. Software Compatibility

Ensure that the engraving software is compatible with your existing design tools, such as CAD or 3D modeling programs. User-friendly software with a wide range of features can significantly enhance your workflow.

Future Trends in Laser Engraving Technology

The field of laser engraving is constantly evolving, driven by advancements in technology and growing demand for customized products. Some emerging trends to watch include:

- AI-Driven Automation: Machine learning algorithms are being integrated into laser engraving software to optimize designs, reduce waste, and improve efficiency.

- Sustainability: Eco-friendly lasers and materials are becoming more popular as manufacturers seek to minimize their environmental impact.

- Customization on Demand: With the rise of e-commerce, businesses are increasingly turning to laser engravers for personalized products that can be produced quickly and efficiently.

Frequently Asked Questions (FAQ)

1. What is the difference between a laser engraver and a 3D printer?

A laser engraver uses focused light beams to etch or cut materials, while a 3D printer builds objects layer by layer using thermoplastic filaments. The two technologies can complement each other, with laser engravers often used for finishing touches on 3D-printed objects.

2. Can I use a laser engraver for cutting metals?

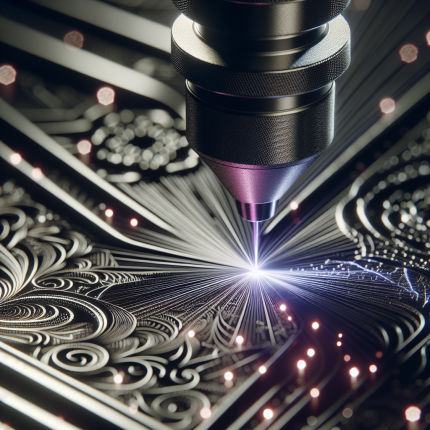

Yes, but it depends on the type of laser. Fiber lasers are particularly effective at cutting through metals like steel and aluminum due to their high power output and precision.

3. How much maintenance do laser engravers require?

Laser engravers typically require regular cleaning of lenses and mirrors, as well as calibration to ensure optimal performance. Dust extraction systems can help reduce maintenance needs over time.

4. Is it expensive to buy a laser engraver?

The cost of a laser engraver varies widely depending on its specifications and intended use. Entry-level models may be affordable for hobbyists, while industrial-grade machines come with a higher price tag.

5. What materials are not suitable for laser engraving?

Materials like certain types of glass, ceramics, and very thick metals can be challenging to engrave with standard lasers. Always test the material on a small scale before committing to a project.

Conclusion

The best laser engraving machine is a powerful tool that combines precision, versatility, and speed to meet the demands of modern manufacturing. Whether you’re working on custom designs, prototyping, or industrial applications, investing in a high-quality laser engraver can significantly enhance your productivity and creativity. By understanding the technical specifications, applications, and trends in this field, you can make an informed decision that aligns with your needs and goals.

Haruki Wu (verified owner) –

The laser engraver excels in performance across various materials, delivering crisp results on wood and acrylic, though leather requires precise speed adjustments for optimal finish. The setup was straightforward, thanks to clear documentation and a user-friendly interface that supports quick project uploads. Compared to competitors, its larger workspace offers versatility, ideal for small businesses or artists tackling detailed projects like custom signage or intricate jewelry engravings. While the price-performance ratio is favorable, investing in additional nozzles could enhance versatility further.

Ling Moore (verified owner) –

The laser engraver has been a reliable tool for my projects. It excels on materials like wood and acrylic, offering precise engravings with adjustable speed settings. Setup was straightforward, and the intuitive software allows seamless design imports. Compared to older models, this one offers better precision and faster processing times. A minor suggestion would be enhanced power options for darker wood tones. Overall, it’s a solid choice for hobbyists and small businesses seeking consistent quality.

Michelle Takahashi (verified owner) –

**Laser Engraver Experience Review**

As a craft store owner, I’ve had the opportunity to work extensively with a laser engraver, and it has been a game-changer for my business. Here’s a concise breakdown of my experience:

### **Technical Performance**

– **Power and Precision:** The laser engraver consistently delivers sharp, precise engravings across various materials like wood, metal, and acrylic. Its adjustable power settings allow for clean cuts and engravings without damaging the material.

– **Software Experience:** The accompanying software is user-friendly, with features like touch-up tools and vector alignment that save time. Custom templates have streamlined my workflow for recurring designs.

– **Special Features:** The engraver’s precision on metal was a revelation—I could achieve intricate details on wedding favors that were previously impossible.

### **Business/Creative Impact**

– **Workflow Improvement:** The laser engraver has significantly sped up production, especially for custom orders. It’s now easier to handle rush jobs and scale projects without compromising quality.

– **Customer Feedback:** Customers consistently praise the uniqueness and quality of engravings, particularly on wedding decorations. Many return for repeat business or recommend my services.

– **Return on Investment:** The initial cost was substantial, but it paid off quickly through increased revenue from custom work. It’s become a cornerstone of my store’s offerings.

Overall, this laser engraver has transformed how I approach creativity and customer satisfaction, making it an invaluable tool for my craft business.

Hiroshi Davis –

“Exceptional laser engraver! Precise cuts, intuitive software, swift operation, and robust build quality. Highly reliable and a true game-changer for my workshop. ⭐⭐⭐⭐⭐”