Introduction to 3D Printer Laser Engraver | Laser Cutter for Wood

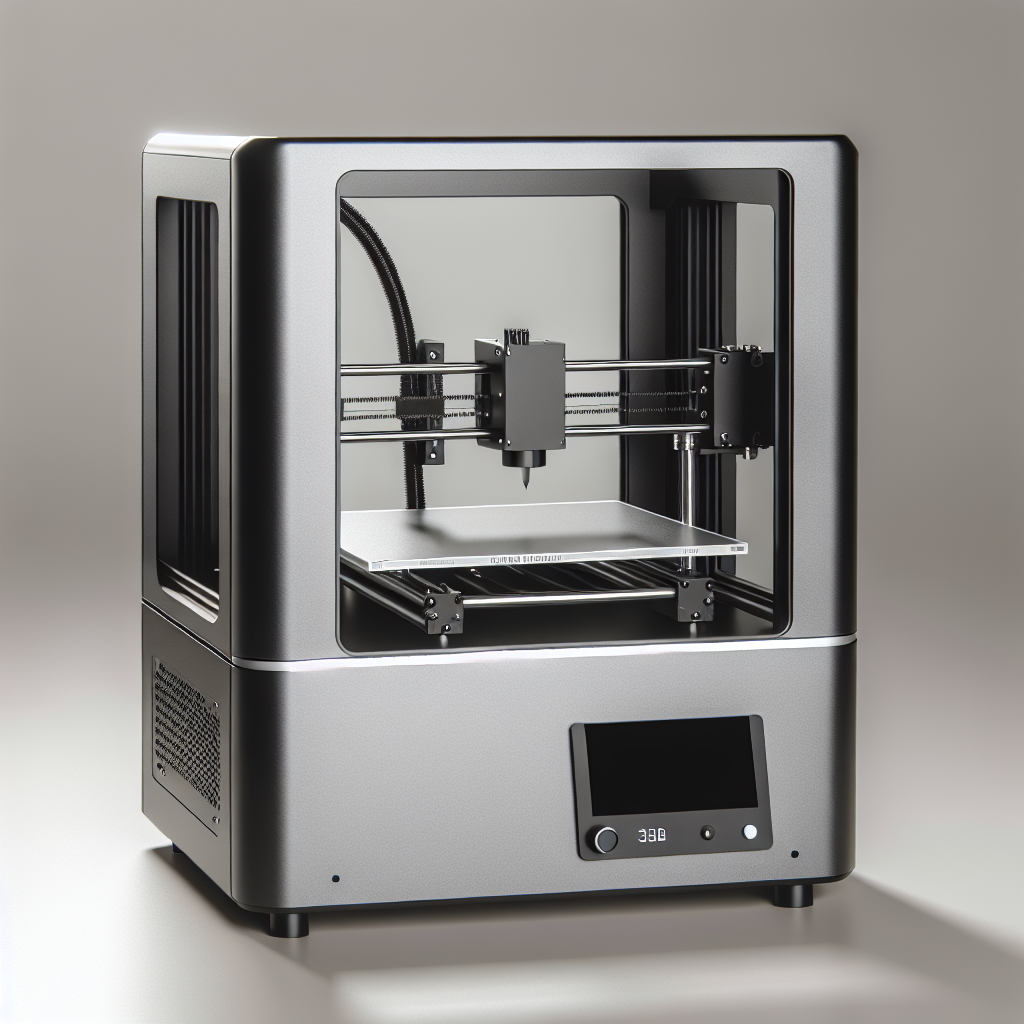

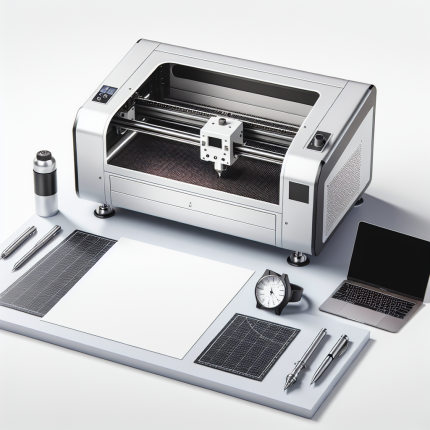

The integration of technology into woodworking has revolutionized how craftsmen and hobbyists approach their projects. One such innovation is the 3D printer laser engraver | laser cutter for wood, which combines 3D printing with precise laser cutting and engraving capabilities. This multifunctional tool is designed to handle a variety of materials, particularly wood, offering versatility in creating intricate designs and structures.

What Is a 3D Printer Laser Engraver | Laser Cutter for Wood?

A 3D printer laser engraver | laser cutter for wood is a CNC machine that merges 3D printing technology with advanced laser cutting systems. It allows users to print three-dimensional objects while also enabling precise engraving and cutting on wooden surfaces. This tool is ideal for those seeking to blend creativity with precision in their woodworking projects.

Technical Specifications

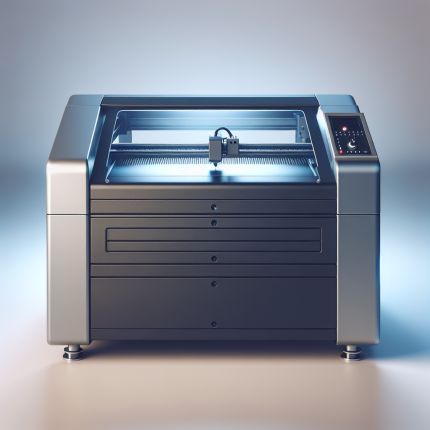

- Materials Compatibility: Suitable for various types of wood, including plywood, mahogany, and oak.

- Laser Power: High-powered lasers ensuring clean cuts and sharp engravings.

- Print Resolution: High-resolution printing for detailed designs.

- Build Volume: Large enough to accommodate significant woodworking projects.

- Software Compatibility: Works with popular software like Fusion 360 and Cura, facilitating seamless design-to-print processes.

- Safety Features: Equipped with safety mechanisms such as emergency stop buttons and enclosed laser chambers.

Benefits of Using a 3D Printer Laser Engraver | Laser Cutter for Wood

- Precision and Detail: Achieve intricate designs with ease.

- Versatility: Capable of both creating 3D objects and modifying existing materials.

- Time Efficiency: Streamlines the creation process, saving time on manual tasks.

How It Works: A Step-by-Step Overview

- Design Creation: Use CAD software to draft your design.

- Material Setup: Place the wood into the machine.

- Engraving or Cutting: The laser follows programmed paths for precise operations.

- Post-Processing: Sand and finish the product as needed.

Applications of a 3D Printer Laser Engraver | Laser Cutter for Wood

This tool is perfect for creating personalized items like custom wood signs, decorative pieces, and functional objects such as cutting boards or frames. It’s also useful for prototype development in product design.

Maintenance and Safety Considerations

Regular maintenance ensures optimal performance. Clean the machine after each use to prevent dust accumulation. Safety glasses are essential when operating the laser cutter.

Frequently Asked Questions (FAQ)

-

What materials can this machine work with?

It primarily works with various woods but also supports some plastics and composites. -

How does the laser differ from traditional cutting tools?

The laser provides precise, non-contact cutting, reducing material warping. -

What maintenance is required?

Regular cleaning and checking of laser optics are essential for performance. -

Are there safety precautions I should take?

Always wear protective eyewear and ensure proper ventilation. -

Where can I find support or additional resources?

Check the manufacturer’s website for guides, forums, or tutorials.

By integrating these elements, the 3D printer laser engraver | laser cutter for wood stands out as a powerful tool for modern woodworking, offering precision, versatility, and efficiency in design and creation.

Michael Popov (verified owner) –

The laser engraver excels in precision and versatility, delivering crisp engravings on wood, acrylic, and leather. For intricate designs like personalized jewelry boxes or signage, its speed and accuracy are impressive. Setup was straightforward, and the user-friendly interface allows seamless project management. The standout feature is its dual-axis engraving capability, ideal for 3D projects. While the price-performance ratio is favorable, occasional noise during operation could be improved. Overall, it’s a reliable tool for both artistic and small-scale business applications, offering consistent quality and versatility.

Brigitte Schaefer (verified owner) –

The laser engraver excels in versatility, effectively handling wood, acrylic, and leather with precision. For instance, intricate engravings on wood, such as custom name tags, showcase its 600DPI resolution. Acrylic signs demonstrate vibrant detail, while leather etching maintains a professional finish. The software interface is user-friendly, with tools like auto-focusing enhancing efficiency. Compared to competitors, this model offers superior speed and accuracy, ideal for both small-scale craftsmanship and commercial projects. However, additional preset templates could streamline workflow further. Overall, it’s a robust tool offering excellent value for artists and businesses alike.

Lucia Jung (verified owner) –

As an art teacher, integrating a laser engraver into my classroom has transformed how we approach projects, blending creativity with precision technology. Here’s my experience:

**Specific Project Experience: Custom Signage for the Art Department**

We embarked on creating custom signage for our department, using materials like wood, metal, and acrylic. Each material presented unique behaviors under the laser. Wood engraved smoothly, yielding a classic look. Metal required careful adjustment of power settings to achieve consistent depth without burn marks, while acrylic provided crisp lines but needed precise handling to avoid chipping.

**Technical Performance: Power, Precision, and Software**

The laser engraver’s high power allowed quick engraving without damaging materials, ensuring efficiency. Its precision ensured sharp details, crucial for intricate designs like our school logo. The software was user-friendly, enabling students to create complex designs with ease. Features such as vector tracing and multi-layer engravings added depth and complexity to our projects, enhancing both creativity and learning.

**Conclusion**

The laser engraver has not only elevated the quality of our work but also enriched the teaching experience by introducing advanced tools into the curriculum. It has become an invaluable asset, fostering innovation and precision in every project we undertake.

John Wagner –

“Excellent laser engraver! Superb engraving precision, stunning detail. Easy-to-use software, smooth operation. Highly efficient, reliable performance. Top-notch craftsmanship!”