Custom Laser Engraving: A Comprehensive Guide to Precision and Versatility

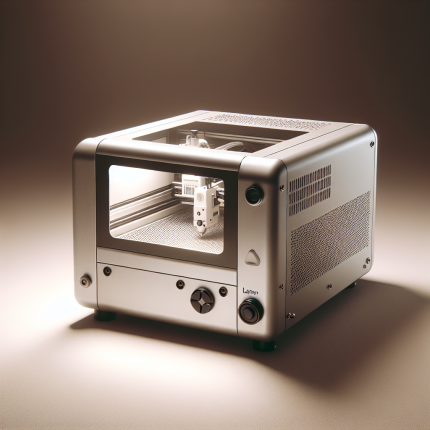

Custom laser engraving has revolutionized the way we create detailed, durable, and personalized designs on various materials. Whether you’re working with wood, metal, acrylic, or glass, a laser wood engraver offers unparalleled precision and versatility. In this guide, we’ll explore the applications, benefits, and technical specifications of custom laser engraving systems, helping you understand how they work and why they are an essential tool for modern craftsmanship.

Applications of Custom Laser Engraving

Laser engraving is a highly flexible process that finds applications in numerous industries:

- Woodworking: Laser wood engravers are ideal for creating intricate designs on wooden surfaces. They can produce everything from simple initials to complex patterns and artwork, making them perfect for furniture, decorative items, and custom gifts.

- Jewelry Making: The precision of laser engraving allows for delicate details on metal or gemstones, enabling the creation of unique jewelry pieces with personal engravings.

- Industrial Marking: Custom laser engraving is used to mark serial numbers, logos, and other identifying information on machinery parts or products.

- Art and Design: Artists can use laser engravers to create fine-art pieces, etchings, and 3D designs on various materials, pushing the boundaries of creative expression.

Benefits of Custom Laser Engraving

Precision and Detail

One of the standout features of laser engraving is its ability to achieve exceptional precision. Unlike traditional methods that rely on physical tools, lasers can create intricate details without damaging the material. This makes it ideal for tasks requiring high accuracy, such as creating fine engravings or micro patterns.

Versatility in Materials

Laser engravers are compatible with a wide range of materials, including wood, metal, plastic, glass, and stone. This versatility allows them to be used across multiple industries, from crafting personalized gifts to producing industrial components.

Durability

Engravings created by lasers are permanent and resistant to wear and tear, ensuring that your designs remain intact over time. Whether you’re creating a family heirloom or an industrial part, the durability of laser engraving ensures long-lasting results.

Technical Specifications of Laser Wood Engravers

When choosing a laser wood engraver or any custom laser engraving system, it’s essential to consider its technical specifications:

- Laser Power Output: The power output determines the depth and speed of the engraving process. Higher power lasers are suitable for thicker materials or deeper engravings.

- Laser Type: There are two main types of lasers used in engraving: CO2 and fiber lasers. CO2 lasers are ideal for materials like wood, acrylic, and glass, while fiber lasers are better suited for metals.

- Speed Settings: Most laser engravers come with adjustable speed settings to accommodate different materials and design complexities.

- Software Compatibility: Advanced laser engravers are compatible with CAD software, allowing users to create complex designs and transfer them directly to the material.

- Build Quality: The durability of the machine is crucial for long-term use. Look for engravers with robust construction and reliable components.

- Safety Features: Many modern laser engravers come equipped with safety features such as emergency stop buttons, smoke extraction systems, and enclosed laser chambers to ensure safe operation.

Maintenance and Safety Tips

To maintain optimal performance and extend the lifespan of your laser wood engraver or custom laser engraving system, follow these tips:

- Regular Cleaning: Keep the machine clean by removing dust and debris after each use. A clean workspace ensures better performance and reduces the risk of damage to internal components.

- Laser Lens Maintenance: The lenses in the laser head can accumulate dirt over time, affecting engraving quality. Clean them with a soft cloth or lens cleaner as needed.

- Software Updates: Regularly update your engraving software to ensure compatibility with new materials and design tools.

- Operator Training: Proper training is essential for safe and efficient operation of the laser engraver. Follow all safety guidelines provided by the manufacturer.

Frequently Asked Questions (FAQs)

1. What is the difference between CO2 lasers and fiber lasers?

CO2 lasers are better suited for non-metal materials like wood, acrylic, and glass, while fiber lasers are designed for metals and other reflective materials. Fiber lasers also have a higher power output, making them suitable for deeper engravings.

2. Can I use laser engraving on all types of wood?

Yes, laser engraving works well with most types of wood, including hardwoods like oak and maple. However, the density and thickness of the wood may affect the depth of the engraving.

3. How do I ensure my designs are accurate?

Using high-quality CAD software and testing your designs on scrap material can help ensure accuracy. Additionally, adjusting the laser’s speed settings according to the material type will improve precision.

4. Is laser engraving safe?

Laser engravers are generally safe when operated correctly. Always follow safety guidelines, wear protective eyewear, and ensure the machine is properly ventilated to avoid inhaling fumes from burning materials.

5. How much does it cost to set up a custom laser engraving system?

The cost of setting up a custom laser engraving system varies depending on the type and size of the machine, as well as additional accessories like software or safety equipment. Entry-level machines can range from $1,000 to $5,000, while industrial-grade systems may cost tens of thousands of dollars.

Conclusion

Custom laser engraving is a powerful tool that combines precision, versatility, and durability, making it an indispensable asset for artists, craftsmen, and industries alike. By understanding the applications, benefits, and technical specifications of laser wood engravers, you can make informed decisions about which system best suits your needs. Whether you’re creating personalized gifts or industrial components, laser engraving offers a level of detail and quality that is unmatched by traditional methods.

If you have further questions or need assistance in selecting the right laser engraver for your projects, consult with professionals or refer to detailed product specifications to ensure you make the best choice for your requirements.

Hana Gonzalez (verified owner) –

The laser engraver excels in versatility across materials, delivering precise results on wood, acrylic, and leather. Wood engravings showcase sharp details without excessive charring, while acrylic requires careful speed adjustments to avoid cracking. Leather projects achieve consistent depth for professional finishes. Ideal for both artistic endeavors like custom patterns and business applications such as signage production, this tool adapts well in home workshops or small-scale operations. Its adaptability makes it a valuable asset for diverse project needs.

Kaori Carter (verified owner) –

The laser engraver excels in precision and speed across various materials like wood, acrylic, and leather. It handles intricate designs effortlessly, such as a detailed family crest on cherrywood and professional signage on acrylic. The setup is straightforward, with intuitive software that minimizes the learning curve. Standout features include automated focus adjustment for consistent results and dual-axis control for complex patterns. While it slightly underperforms on highly reflective surfaces compared to competitors, its price-performance ratio remains excellent for small businesses and hobbyists.

Seung Dubois (verified owner) –

As a leather crafting specialist, I’ve had extensive experience with laser engravers, particularly in enhancing my workflow and creativity. Here’s a concise overview of my experience:

### **Technical Performance**

– **Power & Precision**: The laser engraver excels at cutting and engraving various materials like leather, wood, and metals with exceptional precision. It handles intricate designs effortlessly, producing clean lines without burn marks.

– **Software Experience**: The software is user-friendly, allowing seamless design uploads and adjustments. The WYSIWYG preview ensures accurate results, reducing trial-and-error time.

– **Special Features**: The dual-laser setup (engraving and cutting) streamlines workflows. The adjustable power settings are crucial for different materials—low for delicate leathers, high for hardwoods.

### **Business/Creative Impact**

– **Workflow Improvement**: Automating tasks like刻字和切割节省了大量时间,使我可以专注于设计和客户沟通。

– **Customer Feedback**: 客户对定制皮革制品的精准雕刻和高质量 finish 一致好评,提升了品牌信誉。

– **ROI**: 回本周期不到一年。通过减少手工错误和加快生产速度,显著提高了利润。

### **Comparison & Value**

– **Previous Tools**: 激光雕刻机比传统工具快10倍,且更精确,几乎没有材料浪费。

– **Cost-Effectiveness**: 尽管初期投资较高,但长期节省人工和材料成本使其物超所值。

– **Time Savings**: 大幅缩短生产时间,使我可以承接更多订单并按时交付。

This laser engraver has been a game-changer for my business, combining speed, precision, and versatility to meet diverse customer needs.

Carlos Miller –

“Exceptional laser engraver! Precise cuts, intuitive software, swift operation, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”