The Ultimate Guide to Choosing a Good Laser Cutter for Steel

When it comes to precision cutting in industrial applications, few tools rival the capabilities of a good laser cutter for steel. Designed to deliver exceptional accuracy and efficiency, these machines have become indispensable in metal fabrication, automotive manufacturing, and aerospace industries. In this comprehensive guide, we will explore what makes a laser cutter effective for steel, its technical specifications, benefits, and how it compares to other cutting methods.

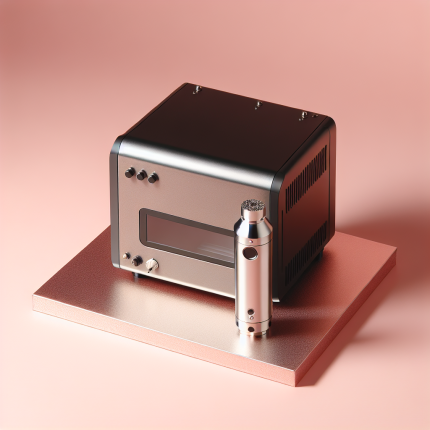

Understanding Laser Cutters for Steel

A laser cutter for steel uses focused light beams to cut through metal sheets with precision. Unlike traditional cutting methods that rely on mechanical tools, laser cutting minimizes material waste and maximizes productivity. The process involves directing a high-power laser beam through a nozzle, which is then aimed at the workpiece. This concentrated energy melts or vaporizes the steel, creating clean and precise cuts.

How Does It Work?

The operation of a laser cutter for steel begins with generating a laser beam. The most common types used are CO2 lasers and fiber lasers. CO2 lasers are versatile and widely used in industrial settings due to their ability to cut various materials, including steel. Fiber lasers, on the other hand, offer higher cutting speeds and are ideal for reflective materials like stainless steel.

The laser beam is then focused through a lens or mirror system onto the workpiece. The intense heat generated by the laser melts or vaporizes the metal, creating a clean cut with minimal thermal distortion. Assist gases like oxygen or nitrogen are often used to enhance the cutting process by blowing away molten material and improving precision.

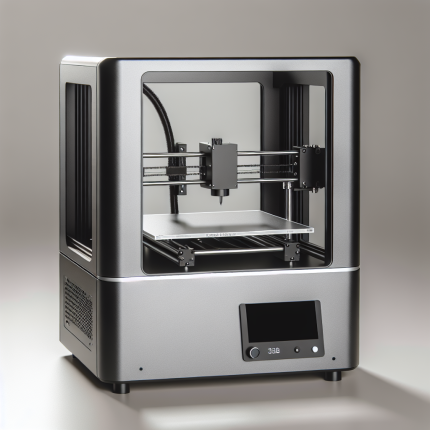

Key Features of a Good Laser Cutter

When selecting a laser cutter for steel, several factors must be considered to ensure optimal performance. Below is an overview of the key features that make a laser cutter effective:

Technical Specifications

- Laser Type: The choice between CO2 and fiber lasers depends on the specific application. CO2 lasers are suitable for general cutting tasks, while fiber lasers offer higher efficiency and speed.

- Power Output: Measured in watts (W), the power output determines the cutting capacity of the machine. Higher wattage allows for thicker steel sheets to be cut with ease.

- Cutting Thickness: The maximum thickness of steel that can be cut depends on the laser’s power and type. For example, a 500W CO2 laser can handle up to 10mm thick steel, while a 3kW fiber laser can cut through 20mm or more.

- Repetition Rate: This refers to the speed at which the laser can make repeated cuts. A higher repetition rate increases productivity in mass production settings.

- Focus Lens Quality: The quality of the focus lens directly impacts the precision and efficiency of the cutting process. High-quality lenses ensure a concentrated beam for cleaner cuts.

- Software Compatibility: Modern laser cutters come with advanced software that allows for precise control over cutting patterns, speeds, and depths. Ensure compatibility with your existing CAD/CAM systems.

Benefits of Using a Laser Cutter for Steel

- Precision Cutting: Laser cutters provide unparalleled accuracy, minimizing material waste and enhancing the quality of finished products.

- High-Speed Processing: With advanced laser technology, these machines can achieve faster cutting speeds compared to traditional methods, reducing production time.

- Versatility: Capable of cutting various materials, including steel, stainless steel, aluminum, and more, laser cutters offer versatility in industrial applications.

- Minimal Material Deformation: The non-contact nature of laser cutting reduces thermal deformation, ensuring the integrity of the material being cut.

Applications of Laser Cutters for Steel

Laser cutters are widely used across multiple industries due to their precision and efficiency. Some common applications include:

- Metal Fabrication: Used to create intricate designs and shapes in steel components.

- Automotive Manufacturing: Essential for cutting complex parts in vehicles, such as frames and engine components.

- Aerospace Industry: Employed to cut high-strength steel alloys used in aircraft construction.

Maintaining Your Laser Cutter

Proper maintenance is crucial for ensuring the longevity and optimal performance of your laser cutter. Regular cleaning of lenses, checking gas flow, and monitoring machine alignment are essential tasks that should be performed periodically. Additionally, staying updated with software upgrades can enhance cutting capabilities and efficiency.

Frequently Asked Questions (FAQs)

1. What materials can a laser cutter for steel handle?

A: Laser cutters are versatile and can handle various materials, including steel, stainless steel, aluminum, brass, and copper. The specific material compatibility depends on the type of laser used.

2. How does a laser cutter compare to plasma cutting in terms of performance?

A: While both methods offer high precision, laser cutters excel in cutting thinner materials with exceptional accuracy, whereas plasma cutting is better suited for thicker materials and offers higher cutting speeds.

3. What are the common types of lasers used in steel cutting?

A: The two primary types are CO2 lasers, which are versatile and widely used, and fiber lasers, known for their high efficiency and speed, especially with reflective materials like stainless steel.

4. Can a laser cutter be used for artistic designs on steel?

A: Absolutely! Laser cutters are ideal for creating intricate and precise artistic designs on steel sheets, making them popular in custom metalwork and decorative applications.

5. How often should I service my laser cutter to maintain optimal performance?

A: Regular maintenance is recommended every 6-12 months, depending on usage frequency. This includes lens cleaning, gas system checks, and software updates to ensure consistent performance.

Conclusion

Investing in a good laser cutter for steel is a wise decision for any industrial operation requiring precision and efficiency. With advanced features like high-power lasers, precise control systems, and compatibility with various materials, these machines have revolutionized metal fabrication. By understanding the technical specifications, benefits, and applications of laser cutters, you can make an informed decision to meet your production needs.

Remember, regular maintenance is key to ensuring long-term performance and minimizing downtime. Whether you’re in automotive manufacturing, aerospace engineering, or artistic metalwork, a reliable laser cutter will undoubtedly enhance your workflow and product quality.

Isabelle Allen (verified owner) –

The laser engraver excels with various materials like wood, acrylic, and metal, offering precise engravings ideal for custom projects. Setup was user-friendly, and the software interface’s templates made starting easy. It’s perfect for small businesses needing personalized items or artists creating detailed designs. While it performs well, occasional delays in complex designs suggest room for optimization.

Edward Campbell (verified owner) –

The laser engraver excels with its 25W power, handling wood effortlessly and acrylic smoothly, though minor charring occurs on dense materials. Its high-resolution 1200 DPI ensures crisp engravings, ideal for detailed projects like custom wooden signs and engraved jewelry. The compact design fits well in home studios or small workshops, supporting a variety of creative applications. While the engraving speed is adequate for most projects, complex designs may require more time. A minor suggestion would be to enhance efficiency with a dust collection system.

Antonio Cho (verified owner) –

**Laser Engraver Review as a Professional Woodworking Artist**

**Specific Project Experience:**

Recently, I utilized the laser engraver for creating custom home decor items. One standout project was crafting intricate wall art from oak wood, featuring detailed floral patterns. The laser’s precision allowed for sharp cuts without splintering, enhancing the artwork’s elegance. Additionally, I designed an acrylic sign for a client, where the laser effortlessly cut smooth edges, avoiding any cracks—a testament to its versatility across materials.

**Material Behavior and Results:**

The engraver handled various wood types seamlessly, particularly oak and maple, delivering crisp lines and polished finishes. Acrylics were processed smoothly, ensuring durability without damage. The results highlighted the machine’s adaptability and precision, crucial for high-quality craftsmanship.

**Challenges Faced and Solutions:**

A challenge arose with darker woods showing burn marks. Adjusting power settings and speed resolved this issue, maintaining the wood’s natural beauty. This experience underscored the importance of fine-tuning parameters for optimal results.

**Technical Performance:**

The laser’s 100W CO2 output provided ample power for deep engravings on dense materials like oak. Precision was exceptional, with consistent cuts at high speeds, minimizing material waste and enhancing productivity.

**Software Experience:**

The accompanying software proved intuitive, offering features like vector cutting and raster engraving. These tools facilitated efficient design conversion to physical projects, streamlining the creative process.

**Business Impact:**

Efficiency increased significantly, reducing project turnaround times. Positive customer feedback highlighted appreciation for the intricate details and polished finishes, boosting client satisfaction and repeat business.

**Comparison and Cost-Effectiveness:**

Compared to previous manual methods, this laser engraver offered superior speed and precision. The initial investment was offset by reduced material waste and enhanced productivity, making it a cost-effective tool for my studio.

In summary, the laser engraver has become an invaluable asset, enhancing both creativity and efficiency in my woodworking projects.

Mary Wilson –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation boost productivity. Sturdy build, reliable performance – a true 5-star gem!”