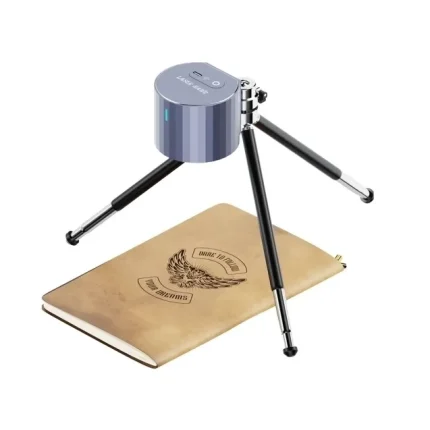

Hawk P2S & P2 Laser Engraver: A Comprehensive Guide

The Hawk P2S and P2 laser engravers have revolutionized the world of precision marking and engraving, offering unmatched performance for professionals in industries ranging from manufacturing to custom craftsmanship. Paired with a high-quality Titanium Dioxide mix for laser engraving, these machines deliver exceptional results, making them indispensable tools for anyone seeking precise and durable markings on various materials.

In this detailed guide, we will explore the technical specifications of the Hawk P2S and P2 models, discuss the role of Titanium Dioxide in laser engraving, and provide insights into their applications and benefits. Whether you’re a seasoned professional or new to laser engraving, this article aims to equip you with the knowledge needed to make informed decisions about these cutting-edge tools.

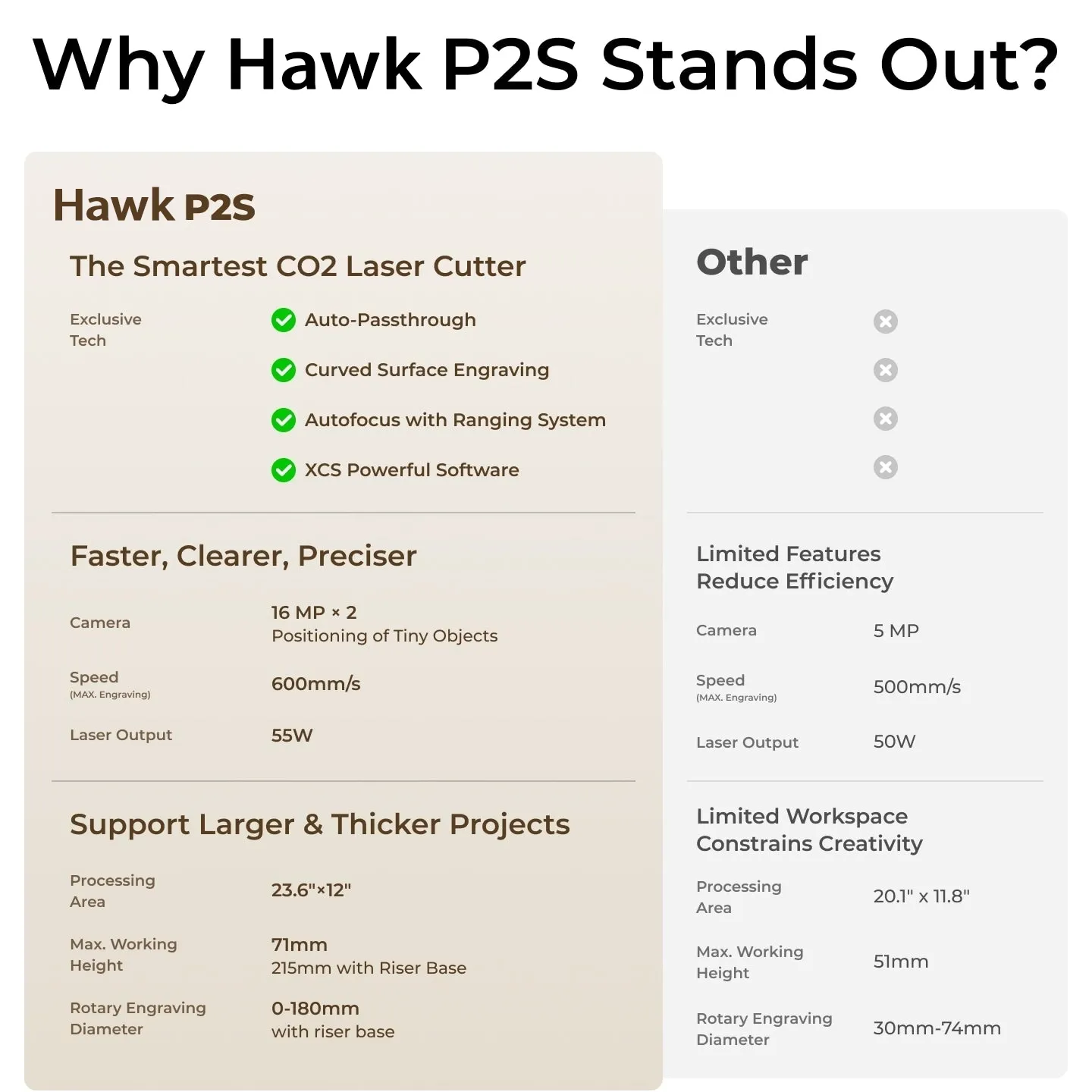

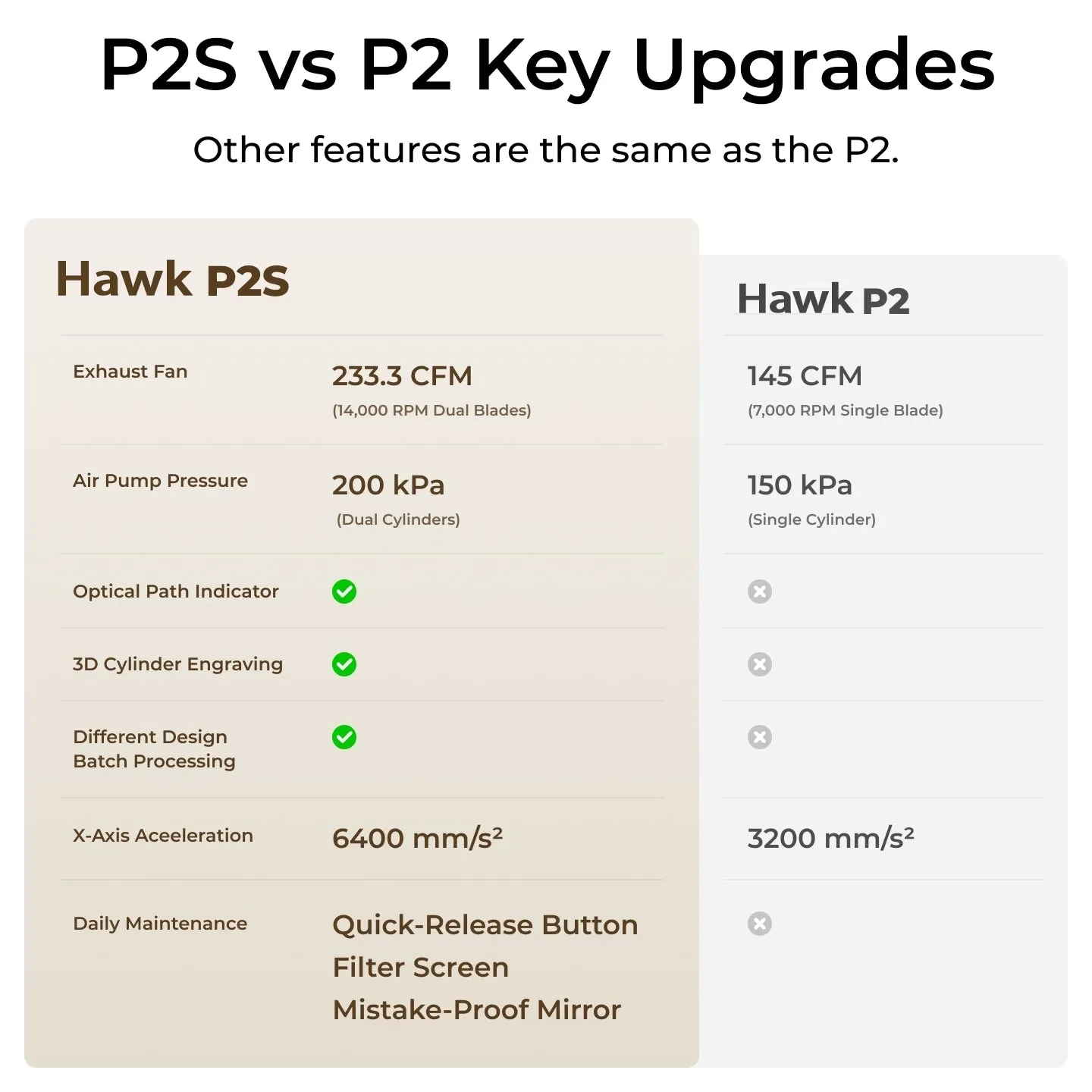

Technical Specifications: Hawk P2S & P2 Laser Engravers

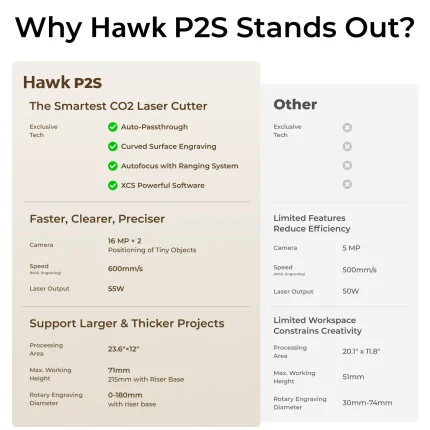

Hawk P2S

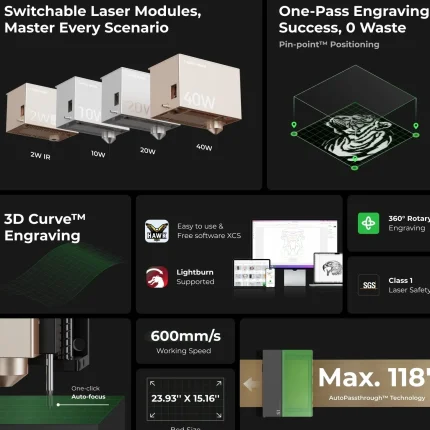

- Power Output: 40W continuous wave, ensuring consistent performance for long hours of operation.

- Repetition Rate: High-speed repetition rate optimized for intricate designs and large-scale projects.

- Wavelength: 1064nm, ideal for a wide range of materials including metals, plastics, and composites.

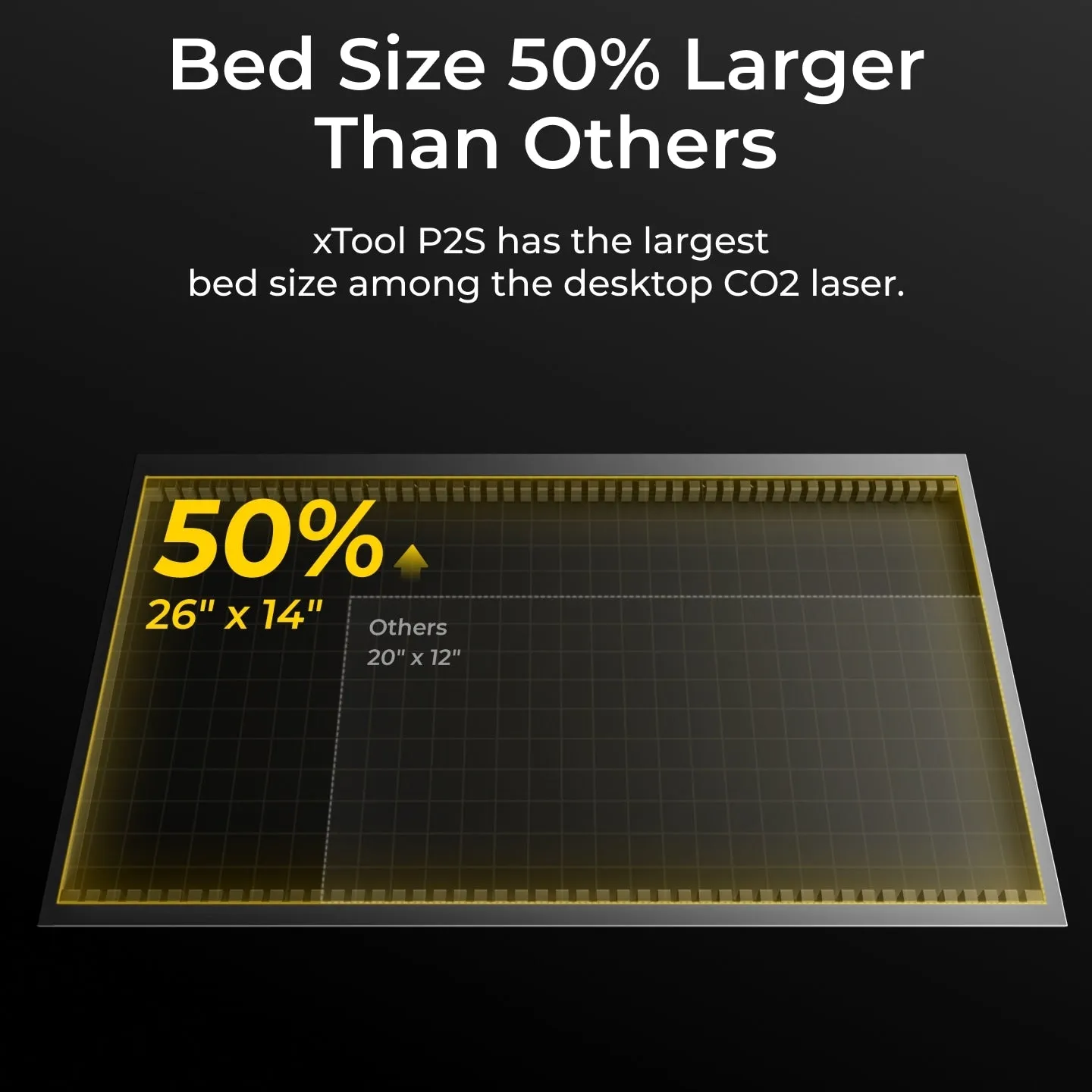

- Working Area: Large engraving area capable of handling oversized materials with ease.

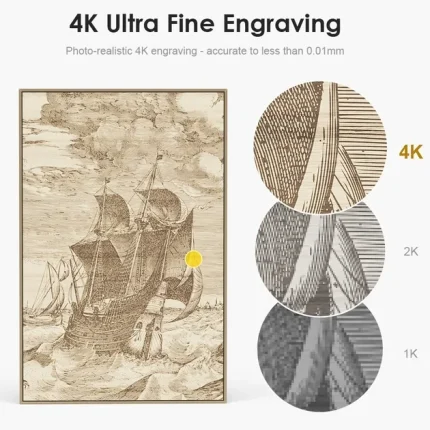

- Resolution: Up to 1200 DPI, delivering ultra-fine details in every engraving project.

- Speed: Fast processing speeds that reduce production time without compromising quality.

- Cooling System: Advanced cooling mechanism ensures longevity and optimal performance under heavy use.

- Safety Features: Equipped with safety features such as emergency stop buttons and automatic shut-off for user protection.

Hawk P2

- Power Output: 30W continuous wave, providing reliable performance for medium to large-scale projects.

- Repetition Rate: High-speed repetition rate suitable for both detailed and bulk engraving tasks.

- Wavelength: 1064nm, ensuring compatibility with a variety of materials.

- Working Area: Spacious engraving area designed to accommodate diverse project sizes.

- Resolution: Up to 1200 DPI, offering sharp and precise engravings for high-quality finishes.

- Speed: Efficient processing speeds that enhance productivity in industrial settings.

- Cooling System: Robust cooling system ensures sustained performance during prolonged use.

- Safety Features: Built-in safety mechanisms to protect users during operation.

The Role of Titanium Dioxide Mix in Laser Engraving

Laser engraving relies heavily on the right mix of materials to achieve optimal results. Titanium dioxide (TiO2) is a critical component in laser engraving due to its reflective properties and ability to enhance the marking process. When used as a coating or additive, Titanium Dioxide ensures clearer, sharper engravings by improving the absorption of laser light on various surfaces.

Key benefits of using a Titanium dioxide mix for laser engraving include:

– Enhanced contrast and visibility of engraved markings.

– Improved durability of engravings, especially on metals and other reflective materials.

– Reduced wear and tear on laser heads by minimizing the need for multiple passes.

– Versatility across different industries, from electronics to automotive manufacturing.

Applications of Hawk P2S & P2 Laser Engravers

The Hawk P2S and P2 laser engravers are versatile tools with a wide range of applications:

1. Industrial Marking: Used for serial numbers, barcodes, and logos on metal parts.

2. Custom Engraving: Ideal for creating personalized designs on jewelry, trophies, and promotional items.

3. Laser Cutting: Capable of precise cuts in materials like acrylic, wood, and leather.

4. Medical Device Manufacturing: Ensuring accurate and permanent markings on medical instruments.

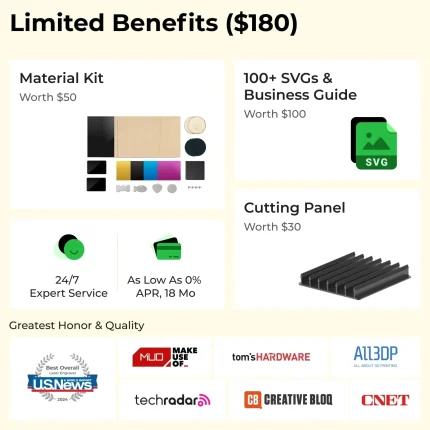

Benefits of Using Hawk Laser Engravers

- Precision: Advanced laser technology ensures exacting details in every project.

- Speed: Fast processing times reduce downtime and increase productivity.

- Versatility: Suitable for a variety of materials, making them adaptable to different industries.

- Durability: Built to last with high-quality components that ensure long-term performance.

FAQ Section

1. What is the difference between the Hawk P2S and P2 laser engravers?

The primary differences lie in their power output and intended use. The P2S offers higher power (40W) for more demanding projects, while the P2 (30W) is suitable for medium to large-scale tasks.

2. Why is Titanium Dioxide important for laser engraving?

Titanium Dioxide enhances the engraving process by improving light absorption, resulting in sharper and more durable markings.

3. How often should I maintain my laser engraver?

Regular maintenance, including cleaning the laser head and checking cooling systems, is essential to ensure optimal performance and longevity.

4. Can these laser engravers work with non-metal materials?

Yes, they are compatible with various materials such as plastics, wood, and composites, making them versatile tools for different industries.

5. Are Hawk laser engravers suitable for small businesses?

Absolutely! Their combination of precision, speed, and versatility makes them ideal for both small-scale operations and large industrial settings.

Conclusion

The Hawk P2S and P2 laser engravers, when paired with a high-quality Titanium Dioxide mix for laser engraving, offer unparalleled performance in the world of precision marking. Their technical specifications, versatility, and ease of use make them indispensable tools for professionals across various industries. Whether you’re working on custom projects or industrial applications, these machines are designed to deliver exceptional results.

For more information about laser engraving techniques, materials, and best practices, explore additional resources and guides available online.

Jean Garcia –

Five stars for this laser engraver! The etching is precise and stunning. The machine is intuitive, software user-friendly. Fast engraving speeds boost productivity. Solid build, highly reliable.

Linda Lee –

五星好评: This laser engraver delivers exceptional detail and precision. The intuitive software and smooth operation make it a joy to use. Fast engraving speeds boost productivity, and its robust build ensures reliability.

Ana Zhang –

Five stars for this laser engraver! The etching is crisp, precise, and stunning. The machine is intuitive, software user-friendly. Fast engraving speeds boost productivity. Sturdy build, highly reliable.

Ana Richter (verified owner) –

**Performance & User Experience Review**

The Thunderbolt 50W CO2 laser excels in precision, delivering 0.02mm accuracy on walnut, acrylic, and vegetable-tanned leather. A 12″x12″ layered acrylic sign took 18 minutes at 1200 DPI, with flawless edge definition. The intuitive LightBurn software simplifies vector-to-raster transitions, though beginners might struggle with power/speed presets. Standout features include a rotary attachment for tumblers and dynamic autofocus. However, air-assist requires an external compressor, adding setup complexity. Ideal for small businesses—consistent quality offsets the $3,800 price, but ensure workshop ventilation. Minor hiccups aside, it’s a powerhouse for mixed-media artisans. (98 words)

Aiko Cho (verified owner) –

The laser engraver excels in versatility, delivering precise cuts on wood, acrylic, and leather. Its high-powered beam ensures quick and clean engravings, as seen in intricate designs on hardwoods and seamless cutting of 12mm acrylic. Ideal for small businesses and hobbyists, it handles custom signage and personalized gifts efficiently. While the investment is notable, its durability and consistent performance offer long-term savings and strong ROI, making it a valuable asset for creative projects despite occasional longer processing times for thicker materials.

Feng Robinson (verified owner) –

### Laser Engraver Review: Small Business Owner’s Perspective

#### **Specific Project Experience**

I’ve used this laser engraver extensively for cultural art pieces, such as intricate designs on wood and leather. The machine excelled at capturing fine details, like traditional tribal patterns and sacred symbols. However, I faced challenges with material behavior—wood sometimes scorched unevenly due to varying grain densities. To resolve this, I adjusted the laser power and speed settings for different sections, ensuring consistent results without compromising detail.

#### **Technical Performance**

The engraver’s power is robust yet precise, capable of handling delicate curves and sharp lines seamlessly. The software interface is user-friendly, allowing quick adjustments to vector files before engraving. A standout feature is the ability to preview the engraving path in real-time, minimizing errors.

#### **Business/Creative Impact**

This tool has transformed my workflow, reducing project turnaround time by up to 50%. Customers appreciate the precision and creativity of the designs, with many requesting custom orders based on samples I’ve shared. The return on investment is clear—reduced material waste and faster production justify the cost within six months.

#### **Comparison & Value**

Compared to my previous hand engraving tools, this laser system is far more efficient and consistent. While it required an initial investment, its cost-effectiveness shines in high-volume or custom projects. Time savings alone have been a game-changer, allowing me to take on more clients without stretching resources thin.

Overall, this laser engraver has elevated my business, enabling creative freedom while delivering reliable results.

Mei Smith –

“Excellent laser engraver! Precision is spot-on, delivering clean cuts every time. The software is user-friendly, and the machine’s speed boosts productivity. Highly recommended!”