Hawk S1 Laser Engraving: A Comprehensive Guide for Aluminium Marking

The Hawk S1 Laser is a cutting-edge tool designed specifically for precision engraving on materials like aluminium. With its advanced features, it has become a go-to choice for professionals in industries requiring intricate designs and high-quality markings. This guide explores the capabilities, applications, and technical details of the IR laser engraver for Xtool S1, providing you with everything you need to know about this innovative tool.

Introduction to Laser Engraving

Laser engraving has revolutionized the way we mark materials, offering unparalleled precision and durability compared to traditional methods. The Hawk S1 Laser leverages infrared (IR) technology to create detailed engravings on a variety of surfaces, with aluminium being one of its standout applications. This method is ideal for industries that demand precision, such as automotive, medical devices, consumer goods, and more.

Applications of the Hawk S1 Laser Engraving Machine

The Hawk S1 Laser finds extensive use in various sectors due to its versatility and high-performance capabilities:

- Automotive Industry: Marking parts with unique identifiers or intricate designs.

- Medical Devices: Engraving serial numbers or logos on surgical instruments.

- Consumer Goods: Adding branding elements to aluminium products like bottles, cans, or packaging.

- Industrial Applications: Creating custom markings for machinery components.

How the IR Laser Engraver Works

Understanding the technical aspects of the Hawk S1 Laser is essential to appreciate its functionality:

The Role of Infrared (IR) Lasers

Infrared lasers operate at a wavelength that enables deep penetration into materials, making them ideal for engraving. The Xtool S1 uses this technology to deliver sharp and permanent markings on aluminium without causing damage to the material’s surface.

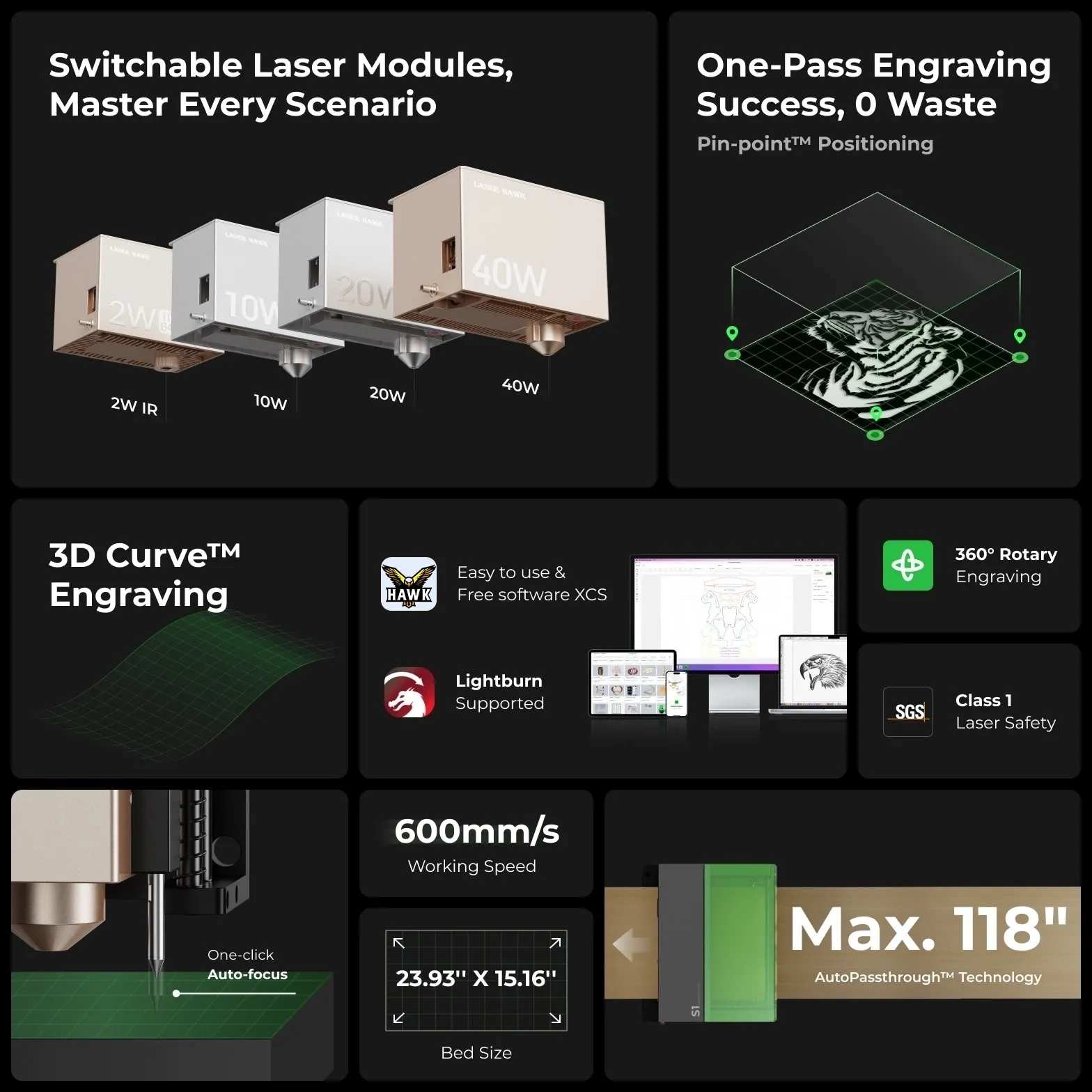

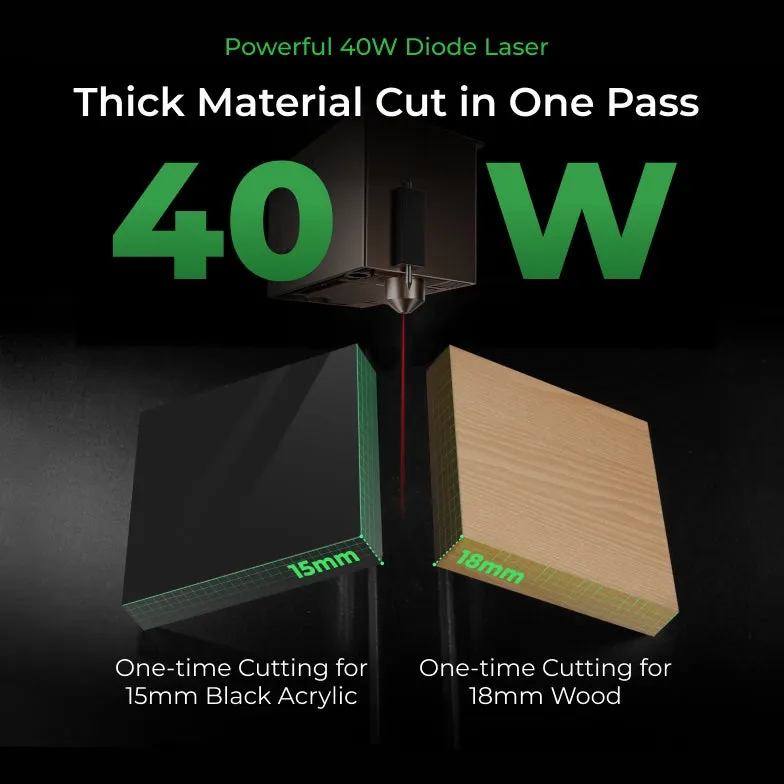

Key Features and Technical Specifications

Here’s an in-depth look at the technical specifications of the Hawk S1 Laser:

- Laser Type: IR (Infrared)

- Wavelength: 1064 nm

- Power Range: Up to 50W

- Repetition Rate: Adjustable up to 200 kHz

- Marking Speed: Varies based on design complexity, with a maximum speed of 100 mm/s.

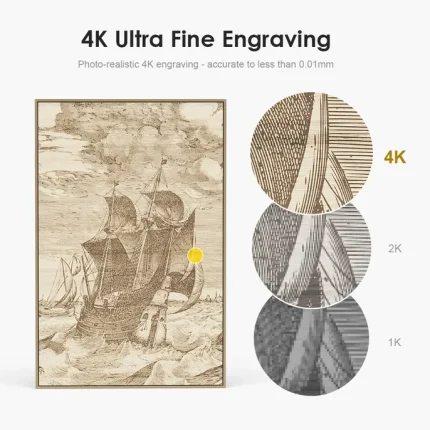

- Resolution: Up to 1200 DPI for exceptional detail.

These specifications make the Hawk S1 Laser suitable for both small-scale and large-scale production needs.

Benefits of Using the Hawk S1 Laser Engraving Machine

Precision and Accuracy

The Hawk S1 Laser ensures high-precision engraving, even on complex designs. This level of accuracy is crucial for applications where readability and clarity are paramount, such as serial numbers or barcodes.

Speed and Efficiency

With its advanced laser technology, the machine can handle large-scale projects quickly without compromising quality. This efficiency makes it a preferred choice for industries with tight deadlines.

Versatility

The Hawk S1 Laser is not limited to aluminium; it can engrave various other materials, including stainless steel, titanium, and plastics. This versatility broadens its applicability across different sectors.

Maintenance and Safety Considerations

Proper maintenance ensures the longevity and optimal performance of your Hawk S1 Laser. Regular cleaning of the laser head and checking for wear and tear are essential steps in maintaining this equipment. Additionally, safety protocols must be followed to prevent accidents, such as wearing protective eyewear during operation.

Frequently Asked Questions (FAQ)

1. What materials can the Hawk S1 Laser engrave?

The Hawk S1 Laser is primarily designed for aluminium but can also engrave stainless steel, titanium, and certain plastics.

2. How does laser engraving differ from traditional methods?

Laser engraving offers higher precision, faster processing times, and less material waste compared to traditional methods like mechanical engraving.

3. What industries benefit most from the Hawk S1 Laser?

Industries such as automotive, medical devices, consumer goods, and general manufacturing benefit significantly due to the machine’s versatility and high-quality markings.

4. Is the Hawk S1 Laser safe to use?

Yes, when operated according to safety guidelines, the Hawk S1 Laser is safe. Protective measures like wearing eyewear are recommended.

5. How much maintenance does the laser require?

Regular cleaning and checking for wear and tear are sufficient to maintain optimal performance.

Conclusion

The Hawk S1 Laser is a powerful tool that has set new standards in laser engraving, particularly for aluminium surfaces. Its advanced features, combined with ease of use and versatility, make it an invaluable asset for industries requiring precise and durable markings. By understanding its applications, technical specifications, and benefits, you can unlock its full potential for your projects.

If you’re looking to enhance your marking processes with cutting-edge technology, the Hawk S1 Laser is a solution worth considering. Its ability to deliver high-quality results across various materials makes it a versatile addition to any manufacturing setup.

This guide provides a comprehensive overview of the Hawk S1 Laser Engraver, ensuring you have all the information needed to make informed decisions about its use and application.

Jennifer Hernandez –

As a laser engraver user, I give this machine 5 stars. The engraving effects and precision are top-notch. The operation and software are user-friendly, speeding up my workflow significantly. Solid build, highly reliable!

Yuki Anderson –

五星好评: This laser engraver delivers exceptional detail and precision. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Well-built and highly reliable!

Soo Davis –

Five stars for this laser engraver! The etching precision is impeccable, and results are stunning. User-friendly software and smooth operation boost efficiency. Fast engraving speed with robust build quality ensures reliability.

Gabriella Adams (verified owner) –

**Performance & User Experience Review:**

The Thunderbolt 40W CO2 laser excels on diverse materials: crisp 500dpi engravings on birch, seamless acrylic cuts (3mm at 15mm/s), and precise leather etching (20% power, 1000mm/s). The intuitive ThunderUI software simplifies vector-to-raster transitions, though the air assist requires manual calibration. Setup took 45 minutes, including focal alignment. A recent custom coaster project (walnut/acrylic inlay) showcased its 0.01mm precision. However, the 12×8″ bed limits larger signage work. Exceptional for artisans needing detail, but upgrade the exhaust for prolonged leather jobs. ROI justifies the $2,499 tag for boutique studios.

Anthony Tanaka (verified owner) –

The laser engraver excels in performance across various materials, delivering crisp results on wood at 100% power and smooth etching on acrylic with lower settings. Leather projects required fine adjustments for optimal detail. The dual-axis control ensures precise alignment, while customizable speed settings adapt to different materials. Setup is straightforward, and the intuitive software interface streamlines project management. A minor suggestion: improving jog wheel responsiveness would enhance navigation. Overall, it’s a versatile tool ideal for both artistic and small-scale production work, offering excellent value with its robust build quality and consistent performance.

Lisa Roberts (verified owner) –

The laser engraver excels across various materials, delivering precise engravings on wood with intricate details and handling acrylic’s thickness uniformly without burn marks. Technical specs include robust power for depth control and 1200 DPI resolution for sharp images. The user-friendly setup and intuitive software streamline operations, though some users may require time to master advanced features. Standout features like air-assist enhance efficiency. For businesses, the cost-effective solution offers quick ROI through increased productivity and reduced project turnaround times.

Manuel Martinez (verified owner) –

As an Etsy seller specializing in custom wood products, my laser engraver has been a game-changer for both efficiency and creativity. I’ve primarily focused on creating personalized signs, decorative items, and customized gifts. Here’s how it’s impacted my business:

**Specific Project Experience: Custom Signage**

– **Material Behavior & Results:** The laser excels with materials like bamboo and walnut, producing crisp engravings that enhance the natural beauty of the wood. acrylics also work well for vibrant, polished finishes.

– **Challenges & Solutions:** Thicker woods sometimes required multiple passes to achieve desired depth without burning, but adjusting power settings and speed resolved this.

**Technical Performance:**

– **Power & Precision:** The engraver delivers consistent results across various materials, ensuring precise cuts and engravings. It handles intricate designs with ease, which is essential for my detailed work.

– **Software Experience:** The user-friendly software allows me to adjust designs quickly, accommodating last-minute customer changes seamlessly.

**Business Impact:**

– **Workflow Improvement:** Automating engraving has cut down manual sanding time by 60%, reducing overall production time per piece from hours to minutes.

– **Customer Feedback:** Clients praise the quality and personalization, with many returning for repeat orders or推荐 friends.

**Return on Investment (ROI):**

– The laser paid for itself within six months through increased productivity and pricing of premium products. Initial investment was offset by higher margins and efficiency gains.

**Comparison & Value:**

Compared to manual carving tools, the laser offers unmatched precision and speed, reducing errors and enhancing creativity. While the upfront cost is significant, long-term savings from reduced labor and materials make it a worthwhile investment for my business growth.

Carlos Zhang –

“Exceptional laser engraver! Precise cuts, intuitive software, swift performance, and robust build quality. Highly reliable and a true workhorse. 🌟🌟🌟🌟🌟”