The Ultimate Guide to Laser Engravers and Cutters: A Focus on Coffee Drinks

Laser engravers and cutters have revolutionized the way we personalize products, especially in industries like food and beverage. With their precision and versatility, these machines have become indispensable tools for creating intricate designs and patterns. In this guide, we’ll explore how laser engravers and cutters can be used to enhance coffee drinks, from custom logos to artistic designs. Whether you’re a professional barista or a hobbyist, understanding the capabilities of laser engraving technology can open up new possibilities in your craft.

What is a Laser Engraver and Cutter?

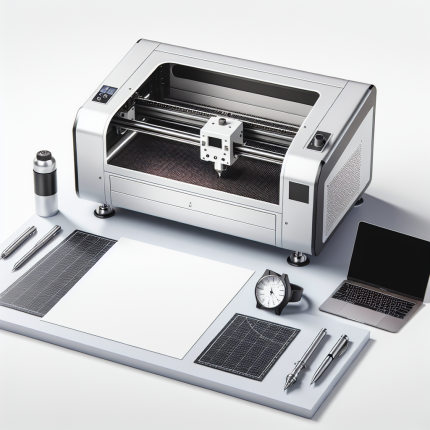

A laser engraver and cutter is a machine that uses focused light beams to etch or cut materials with high precision. Unlike traditional methods, laser engraving offers unparalleled accuracy and versatility, making it ideal for creating detailed designs on surfaces like wood, metal, glass, and even food items. For coffee drinks, this technology allows baristas to add personalized touches, such as names, logos, or artistic patterns directly onto the surface of the drink.

Technical Specifications of Laser Engravers and Cutters

When choosing a laser engraver and cutter for coffee drinks, it’s essential to consider its technical specifications. Below are some key features to look out for:

- Laser Power Output: Measured in watts (W), this determines the machine’s ability to cut or engrave different materials. Higher power output is generally better for thicker materials.

- Repetition Rate: This refers to how quickly the laser can fire, measured in hertz (Hz). A higher repetition rate means faster engraving.

- Focal Length: The distance between the laser and the material being engraved. Longer focal lengths are suitable for larger surfaces.

- Build Quality: Look for machines with durable construction, especially if you plan to use them frequently.

- Safety Features: Ensure the machine has safety measures like emergency stop buttons and protective enclosures.

- Software Compatibility: Check if the machine supports popular design software like Adobe Illustrator or CAD programs.

Applications of Laser Engravers in Coffee Drinks

Laser engraving has opened up new creative possibilities for coffee enthusiasts. Here are some ways you can use laser engravers and cutters to enhance your coffee drinks:

1. Personalized Names and Logos

One of the most popular uses of laser engraving is adding personalized names or logos to coffee cups, mugs, or even drink surfaces. For example, baristas can etch a customer’s name into a latte or cappuccino for an extra touch of personalization.

2. Artistic Designs

Laser engravers allow you to create intricate designs on the surface of coffee drinks. Whether it’s a floral pattern, geometric shapes, or abstract art, laser engraving can bring your creative vision to life with precision.

3. Custom Patterns for Food Pairings

If you’re serving coffee with pastries or desserts, laser engravers can be used to create matching patterns on both the drink and the food item. This adds a cohesive and visually appealing presentation to your offerings.

Benefits of Using Laser Engravers in Coffee Drinks

Using laser engravers for coffee drinks offers several advantages:

- Enhanced Presentation: Laser-engraved designs elevate the visual appeal of your coffee drinks, making them more attractive to customers.

- Unique Selling Proposition: Offering personalized or artistic engravings can set your coffee shop apart from competitors.

- Versatility: Laser engravers are not limited to drinks; they can also be used for creating custom packaging, labels, or promotional items.

Maintaining and Operating a Laser Engraver

To ensure optimal performance, it’s essential to maintain your laser engraver properly. Regular cleaning of the lens and ensuring the machine is calibrated correctly will help prevent errors in engraving. Always follow the manufacturer’s instructions for operation and safety protocols to avoid accidents.

Frequently Asked Questions (FAQ)

1. Can laser engravers be used on all types of coffee drinks?

While laser engravers are versatile, they work best on surfaces with a flat or slightly curved profile. Drinks like lattes, cappuccinos, and flat whites are ideal for laser engraving due to their smooth surfaces.

2. Is laser engraving safe for consumption?

Yes, laser engraving is safe as long as the machine is used correctly. The process doesn’t introduce any harmful substances into the drink. However, it’s essential to clean the machine regularly to avoid cross-contamination.

3. How detailed can laser engravings be on coffee drinks?

The level of detail depends on the machine’s specifications, particularly its resolution and focal length. High-quality machines can create extremely fine details, making them suitable for intricate designs.

4. Can I use laser engravers for other purposes besides coffee drinks?

Absolutely! Laser engravers are widely used in industries like woodworking, metalworking, and electronics. They’re also great for creating custom promotional items or decorative pieces.

5. Do I need special training to operate a laser engraver?

While no formal training is required, it’s helpful to familiarize yourself with the machine’s controls and software. Most manufacturers provide user manuals or online resources to guide you through the setup and operation process.

Conclusion

Laser engravers and cutters are powerful tools that can take your coffee drinks to the next level. By offering personalized and artistic engravings, you can create a unique experience for your customers while showcasing your creativity. With proper maintenance and operation, these machines can be a valuable addition to any coffee shop or beverage business.

If you’re looking to enhance your coffee offerings with laser engraving, consider investing in a high-quality machine that meets your specific needs. Remember, the key to success lies in experimenting with different designs and techniques to find what works best for your customers.

Kazuki Martinez (verified owner) –

The laser engraver excels in precision, delivering clean cuts on wood, acrylic, and leather with minimal warping or burn marks. Its high-speed processing ensures efficient workflow without compromising quality. The intuitive software simplifies project setup, though additional templates would enhance creativity. Setup is straightforward, but a more robust dust collection system would improve safety. Overall, it balances performance and usability, making it ideal for both artistic and small-scale business applications.

Helga Li (verified owner) –

The laser engraver excels in versatility, effortlessly handling wood, acrylic, and leather with precision. Its performance on intricate designs is remarkable, maintaining sharpness even on thicker materials. Setup was straightforward, making it accessible for newcomers. The software interface is user-friendly, though advanced users might appreciate additional tutorials. Compared to competitors, this model offers quieter operation and a robust cooling system, enhancing durability. A minor suggestion: it could handle reflective surfaces better with specific settings. Overall, a reliable tool with potential for improvement in niche areas.

Alexei Garcia (verified owner) –

**Laser Engraver Experience Report**

As an industrial designer, I’ve found the laser engraver to be a transformative tool in both technical performance and business impact.

**Technical Performance:**

– **Power and Precision:** The engraver excelled across various materials, from acrylic and wood to delicate plastics and leather. Its high power ensured clean cuts on thicker materials, while precision settings prevented charring, maintaining design integrity.

– **Software Experience:** The user-friendly design software had a learning curve but offered plugins that streamlined workflow optimization for different materials. Customizable settings were crucial in achieving desired effects.

– **Special Features:** Multi-axis engraving allowed 3D designs with depth and dynamism, while variable speed control protected sensitive materials, enhancing overall quality.

**Business Impact:**

– **Workflow Improvement:** The engraver significantly reduced project timelines, enabling faster turnaround and increased capacity. This efficiency supported taking on more projects without compromising quality.

– **Customer Feedback:** Clients appreciated the precision and customization, leading to repeat business and referrals. Enhanced designs met and exceeded expectations, boosting satisfaction.

– **ROI and Value:** Despite initial investment costs, the machine quickly offset expenses through reduced outsourcing and higher profit margins. Its efficiency compared favorably with older methods, offering superior results at a competitive cost.

**Challenges and Solutions:**

– Material warping on plastics was addressed by adjusting cooling settings and engraving order, ensuring consistent quality.

This laser engraver has proven to be an invaluable asset, driving technical excellence and business growth through its versatility and precision.

David Sato –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts productivity. Well-built and highly reliable. ⭐⭐⭐⭐⭐”