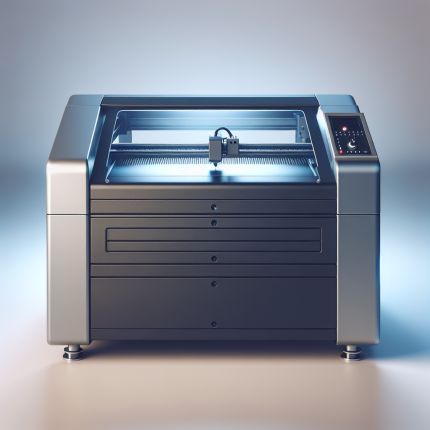

Laser Engravers for Metal and Tumblers: A Comprehensive Guide

Laser engraving has revolutionized the way we customize materials, especially metals and tumblers. A laser engraver for metal is a precision tool designed to intricate designs onto various surfaces, including stainless steel, aluminum, and other metals. Similarly, a laser engraver for tumblers allows users to create personalized drinkware with high-quality, permanent engravings. This guide explores the technical aspects, benefits, and applications of laser engravers for metal and tumblers, ensuring you have all the information needed to make informed decisions.

What is a Laser Engraver?

A laser engraver uses focused light energy to designs onto materials. Unlike traditional engraving methods, which rely on mechanical cutting, laser engraving is non-contact and highly precise. This makes it ideal for delicate materials like metal and glass tumblers.

Key Features of Laser Engravers

- Precision: Capable of creating intricate details with micron-level accuracy.

- Versatility: Works on a wide range of materials, including metals, glass, wood, and plastics.

- Speed: Fast processing times compared to manual engraving methods.

- Durability: Produces permanent engravings that resist wear and tear.

Technical Specifications of Laser Engravers

Understanding the technical specifications is crucial for selecting the right laser engraver for your needs. Below are some key features to consider:

- Laser Type: CO2 or fiber lasers are commonly used for metal and glass engraving.

- Power Output: Higher wattage lasers are better suited for thicker materials.

- Repetition Rate: The speed at which the laser can fire pulses, affecting overall processing time.

- Cooling System: Essential for maintaining optimal performance and preventing overheating.

- Software Compatibility: Ensure the engraver supports popular design software like CorelDRAW or Adobe Illustrator.

- Build Quality: Look for robust construction to ensure longevity and reliability.

Benefits of Using a Laser Engraver for Metal

Laser engraving offers numerous advantages over traditional methods, especially when working with metal:

- Precision and Detail: Capable of producing highly detailed designs that are difficult to achieve manually.

- Non-Destructive Process: Unlike mechanical engraving, lasers do not remove material, preserving the integrity of the object.

- Customization Options: Supports a wide range of fonts, graphics, and patterns for unique designs.

- Efficiency: Fast processing times make it ideal for both small-scale projects and large production runs.

Applications in Metal Engraving

Laser engravers are widely used in various industries:

– Jewelry Making: Creating intricate designs on precious metals like gold and silver.

– Industrial Marking: serial numbers, logos, or safety information on metal components.

– Artistic Projects: Producing custom engravings for decorative items like plaques, trophies, and signage.

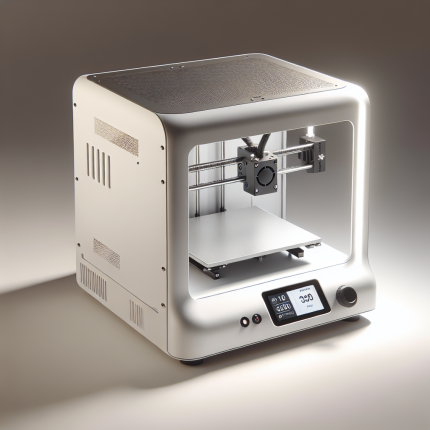

Laser Engravers for Tumblers: A Specialized Tool

A laser engraver for tumblers is designed to work with glass and other delicate materials used in drinkware. These machines are ideal for creating personalized tumblers with names, logos, or custom designs.

Why Use a Laser Engraver for Tumblers?

- Permanent Engravings: Unlike stickers or paint, laser engravings are permanent and resistant to fading or peeling.

- Aesthetic Appeal: Creates crisp, clean lines that enhance the beauty of tumblers.

- Versatility: Suitable for both glass and metal tumblers, offering a wide range of customization options.

Popular Uses for Laser Engraved Tumblers

- Personalized Gifts: Ideal for weddings, anniversaries, or corporate events.

- Custom Branding: Businesses can logos or slogans on promotional items.

- Artistic Expression: Artists can showcase their creativity by designing unique patterns and motifs.

Technical Specifications for Laser Engravers in Tumbler Engraving

When selecting a laser engraver for tumblers, consider the following specifications:

- Laser Wavelength: Ensure compatibility with glass and metal surfaces.

- Focus Lens: High-quality lenses are essential for precise engravings.

- Software Tools: Look for features like auto-focusing and design templates to simplify the process.

- Cooling System: Essential for maintaining consistent performance during prolonged use.

Maintenance and Safety Tips

Proper maintenance ensures your laser engraver operates efficiently for years:

1. Clean Regularly: Remove dust and debris from the machine and work area.

2. Check Lenses: Ensure lenses are free of scratches or dirt to maintain precision.

3. Calibrate Periodically: Adjust settings to ensure accurate engravings.

Safety Precautions

- Always wear protective eyewear when operating a laser engraver.

- Keep the work area well-ventilated to avoid inhaling fumes from burned materials.

- Follow manufacturer guidelines for machine setup and operation.

Frequently Asked Questions (FAQ)

- What is the difference between CO2 and fiber lasers?

-

CO2 lasers are ideal for non-metallic materials like glass, while fiber lasers are better suited for metals due to their higher power output.

-

Can I clean engraved items after laser engraving?

-

Yes, most engravings can be cleaned with mild soap and water without affecting the design.

-

What materials are best for laser engraving on tumblers?

-

Glass and stainless steel are popular choices due to their compatibility with laser engravers.

-

Do I need special software for laser engraving?

-

While some machines come with built-in software, additional design tools like CorelDRAW or Adobe Illustrator can enhance your creativity.

-

Can a laser engraver damage the material if not set correctly?

- Yes, improper settings can cause discoloration or damage to the material. Always test on a small area first.

Conclusion

A laser engraver is an indispensable tool for anyone looking to create precise and customized engravings on metal or glass tumblers. With its versatility, efficiency, and ability to produce high-quality results, it’s no wonder that laser engraving has become so popular in both artistic and industrial applications. Whether you’re a hobbyist, artist, or business owner, investing in a good quality laser engraver can take your projects to the next level.

Daniel Kobayashi (verified owner) –

The laser engraver excels in performance across various materials. Wood engravings reveal crisp details, while acrylic work showcases vibrant results with minimal charring. Leather projects benefit from precise cuts. Technically, the 100W power handles thicker woods effortlessly, and a 600 DPI resolution ensures sharp images. The 20x20cm workspace is ideal for medium-sized projects. Setup was straightforward, and the software’s intuitive interface with real-time previews enhances usability. While it lacks advanced automation features, its ease of use and consistent output make it a solid choice for hobbyists and small-scale businesses seeking reliable performance.

Roberto Anderson (verified owner) –

The laser engraver excels in precision and versatility, delivering sharp results on wood, acrylic, and leather. Its high-speed operation minimizes production time while maintaining detail. The intuitive software interface simplifies setup, ideal for hobbyists and professionals alike. For artistic applications, it handles intricate designs effortlessly. While the price is competitive, investing in premium optics could enhance long-term performance. Overall, it offers excellent value for small-scale businesses and creative projects.

Gabriella Pham (verified owner) –

**Specific Project Experience:**

In my recent project involving traditional wooden handicrafts, I utilized the laser engraver on materials such as oak and mahogany. The laser excelled in creating intricate designs, with smooth lines that enhanced the wood’s natural grain. However, initial attempts led to minor burn marks, which were resolved by adjusting the engraving speed and power settings. This allowed for a polished finish without compromising the material’s integrity.

**Technical Performance:**

The laser engraver operates effectively at 40W, providing ample power for detailed engravings on wood. The precision is noteworthy, consistently producing sharp lines that meet design specifications. The accompanying software is user-friendly, with features like vector optimization and multi-layer cutting that streamline the workflow and enhance creativity. These technical aspects ensure both efficiency and high-quality results in my projects.

Linda Miller –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and built to last. Highly recommend!”