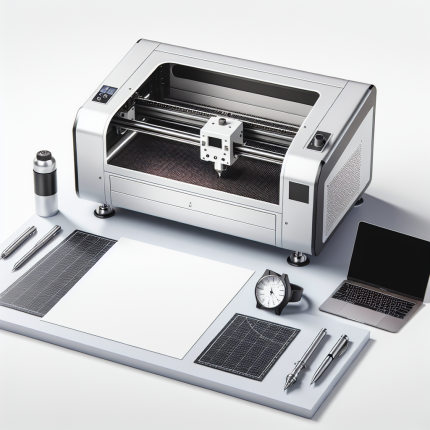

Laser Engraving and Cutting Machines: A Comprehensive Guide

Introduction

In the realm of precision manufacturing and artistic design, laser engraving and cutting machines have emerged as indispensable tools. These machines utilize focused laser beams to etch intricate designs or slice through materials with unparalleled accuracy. Their versatility makes them integral across industries such as jewelry making, sign production, electronics, and medical device manufacturing.

Technical Specifications

Understanding the technical aspects of laser engraving and cutting machines is crucial for selecting the right equipment. Key specifications include:

- Laser Types: CO2 and Fiber lasers, each suited for different materials.

- Power Levels: Ranging from 30W to 10kW, determining speed and material capacity.

- Speed Range: Typically between 1,000mm/s to 5,000mm/s, affecting production efficiency.

- Repetition Rate: Measured in Hz, influencing precision for detailed engravings.

- Software Compatibility: Support for CAD/CAM software like CorelDRAW and AutoCAD.

- Maintenance Requirements: Includes regular cleaning of optics and mirrors.

Applications Across Industries

The adaptability of laser engraving and cutting machines is remarkable:

- Manufacturing: Ideal for creating precise components in electronics and aerospace.

- Jewelry Making: Perfect for delicate engravings on precious metals.

- Signage Production: Efficiently cuts materials like acrylic and wood.

- Medical Devices: Ensures high precision in crafting complex devices.

Benefits Over Traditional Methods

Laser technology offers significant advantages:

- Precision and Accuracy: Capable of detailed work beyond manual capabilities.

- Efficiency: Reduces production time and labor costs.

- Material Versatility: Suitable for metals, plastics, wood, and more.

- Reduced Waste: Minimizes material wastage with precise cuts.

- Customization: Facilitates unique designs tailored to specific needs.

Choosing the Right Machine

Selecting the appropriate laser machine involves several considerations:

- Budget Constraints: Ranges from entry-level to high-end models.

- Intended Use: Determine if the focus is on engraving, cutting, or both.

- Material and Size Requirements: Consider the types of materials and their thickness.

- Training Needs: Availability of support for machine operation.

Maintenance and Safety

Proper upkeep ensures longevity and performance:

- Regular maintenance tasks include cleaning optics and monitoring fluid levels.

- Safety measures involve wearing protective gear and ensuring adequate ventilation.

Future Trends

The evolution of laser technology continues to innovate:

- Integration with AI for automated adjustments in cutting parameters.

- Hybrid systems combining multiple laser types for diverse applications.

- Sustainable practices, such as energy-efficient designs and waste reduction techniques.

FAQ Section

- What is the difference between laser engraving and cutting?

-

Engraving involves surface etching, while cutting severs materials entirely.

-

Which materials are compatible with these machines?

-

Commonly used materials include metals, plastics, wood, glass, and leather.

-

How often does a laser machine require maintenance?

-

Typically every 500-1000 hours of operation to ensure optimal performance.

-

What affects the precision of a laser machine?

-

Factors include laser type, power, and focus lens quality.

-

Can these machines be used for both small and large-scale production?

- Yes, they are versatile for various scales depending on specifications.

Conclusion

Laser engraving and cutting machines have revolutionized numerous industries with their precision and efficiency. By understanding technical specs, applications, benefits, and future trends, businesses can make informed decisions to enhance their operations. This guide serves as a valuable resource for anyone exploring the potential of laser technology in their projects.

Lucia Gonzalez (verified owner) –

The laser engraver excels in versatility, delivering crisp engravings on wood, acrylic, and leather with precision. Its high-resolution optics ensure detailed designs, ideal for custom signs or intricate leather goods. Setup was straightforward, but the learning curve for software customization required some time. The user-friendly interface simplifies project creation, though additional preset options for different materials would enhance efficiency. Overall, it’s a solid choice for small businesses and hobbyists seeking reliable performance at an affordable price.

Viktor Jones (verified owner) –

This laser engraver excels in precision and speed, delivering sharp engravings on wood, acrylic, and leather. For intricate designs, the 10W laser handles detailed patterns effortlessly, while its 25x25cm workspace accommodates both small and medium projects. The software interface is intuitive, with customizable settings for optimal results. I recommend it for businesses needing consistent output or artists exploring creative engraving. Its price-performance ratio is strong, though minor upgrades like an adjustable bed would enhance versatility.

Teresa Roberts (verified owner) –

As a professional woodworking artist, my experience with this laser engraver has been transformative. Focusing on Specific Project Experience and Technical Performance provides a comprehensive view of both application and tool capabilities.

**Specific Project Experience:**

I used the laser engraver to create intricate designs on traditional wooden crafts, such as custom cutting boards and decorative boxes. The precision allowed me to achieve detailed patterns that were previously labor-intensive with hand tools. However, I encountered minor burn marks on darker woods, which I resolved by adjusting the engraving speed and power settings for different materials.

**Technical Performance:**

The laser’s 60W CO2 output provided sufficient power for deep engravings without overwhelming the wood. The precision was remarkable, consistently achieving lines as fine as 0.1mm. The software interface was user-friendly, enabling seamless design imports from Adobe Illustrator and real-time adjustments. I particularly appreciated features like vector engraving, which streamlined my workflow by handling complex patterns effortlessly.

This combination of hands-on project insights and technical prowess highlights how the laser engraver enhances both creativity and efficiency in woodworking.

Klaus Li –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation boost workflow. Fast, efficient, and reliably well-built. Highly recommend!”