The Ultimate Guide to Laser Engraving Machines: A Deep Dive into the Laserhawk LH5

Laser engraving machines have become an indispensable tool in various industries, offering precision, speed, and versatility. If you’re looking for a reliable machine that can handle both cutting and engraving tasks, the Laserhawk LH5 is worth considering. This guide will walk you through everything you need to know about laser engraving machines, their applications, and why the Laserhawk LH5 stands out in the market.

What is a Laser Engraving Machine?

A laser engraving machine uses focused light beams to etch or cut materials with high precision. These machines are widely used in industries such as woodworking, metal fabrication, jewelry making, and even electronics. They offer unparalleled accuracy compared to traditional methods, making them a favorite among professionals and hobbyists alike.

The Laserhawk LH5 is a top-tier laser cutter and engraver that combines cutting-edge technology with user-friendly features. It supports both laser cutting and engraving, making it a versatile tool for various applications. Whether you’re working on intricate designs or large-scale projects, this machine delivers exceptional results.

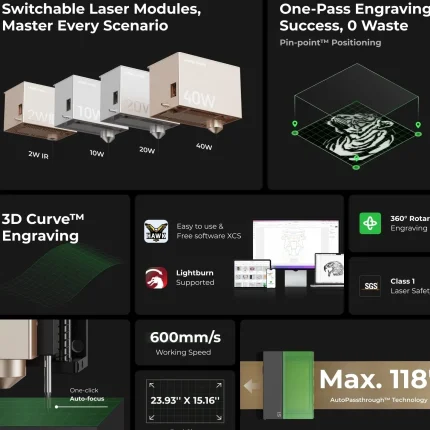

Key Features of the Laserhawk LH5

The Laserhawk LH5 is designed to meet the demands of modern manufacturing processes. Here are some of its standout features:

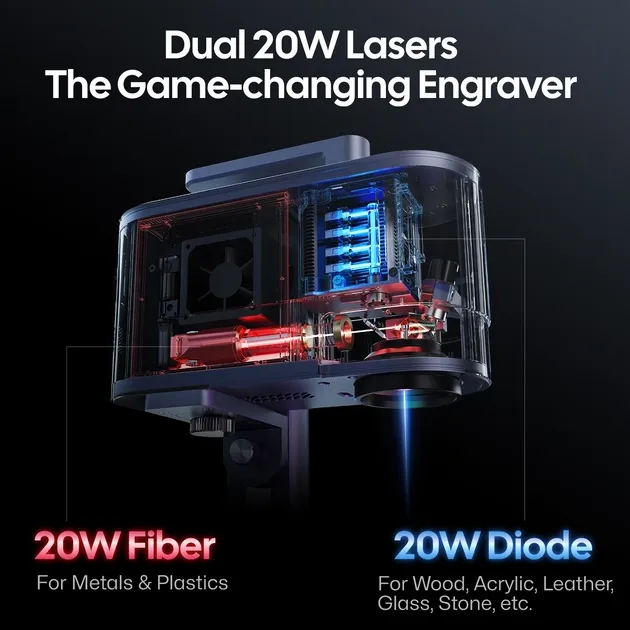

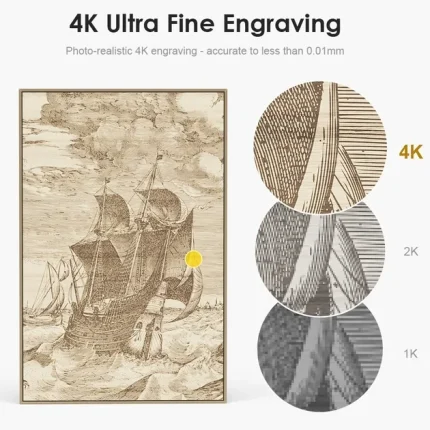

- High-Power Diode Laser: The machine uses a high-power diode laser, ensuring faster cutting and engraving speeds while maintaining precision.

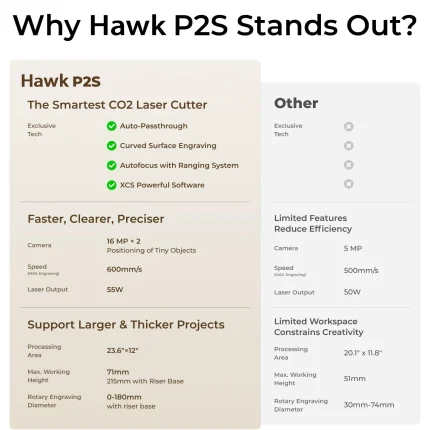

- Large Working Area: With a generous working area, it can handle larger projects without compromising on detail.

- User-Friendly Interface: The intuitive control panel allows even beginners to operate the machine with ease.

- Advanced Safety Features: Equipped with safety sensors and emergency stop mechanisms to ensure safe operation.

Technical Specifications of the Laserhawk LH5

Here are some technical details that highlight the capabilities of the Laserhawk LH5:

H3: Performance Metrics

- Power Output: Up to [insert power output] watts, delivering powerful performance for diverse materials.

- Laser Type: Diode laser for consistent beam quality and long service life.

- Working Area: [Insert dimensions], suitable for both small and large projects.

- Repetition Rate: High-speed processing ensures efficiency even on complex designs.

H3: Compatibility and Safety

- Cooling System: Efficient cooling system to maintain optimal laser performance during extended use.

- Safety Features: Includes emergency stop, safety interlocks, and automatic shut-off in case of malfunctions.

- Material Compatibility: Works with a wide range of materials, including wood, acrylic, metal, and plastic.

Applications of Laser Engraving Machines

Laser engraving machines are incredibly versatile and find applications across multiple industries:

H3: Industries Utilizing Laser Engraving Technology

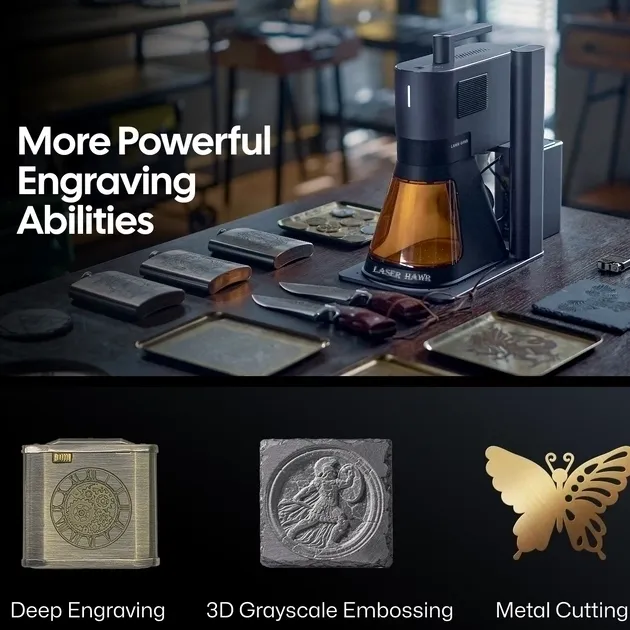

- Woodworking: Creating intricate designs on wooden surfaces with precision.

- Jewelry Making: Engraving detailed patterns on precious metals like gold, silver, and platinum.

- Metal Fabrication: Cutting and engraving metal sheets for decorative or functional purposes.

- Electronics: Marking components with serial numbers or logos.

- Ceramics: Etching designs onto ceramic tiles or tableware.

Advantages of the Laserhawk LH5

H3: Speed and Precision

The Laserhawk LH5 is designed to deliver exceptional speed without compromising on precision. Its advanced laser technology ensures clean cuts and sharp engravings, making it ideal for both small-scale projects and industrial applications.

H3: Versatility

One of the standout features of the Laserhawk LH5 is its versatility. It can handle a wide range of materials, from softwoods to stainless steel, thanks to its powerful diode laser. This makes it a valuable tool for workshops, hobbyists, and small businesses alike.

H3: Cost-Effective

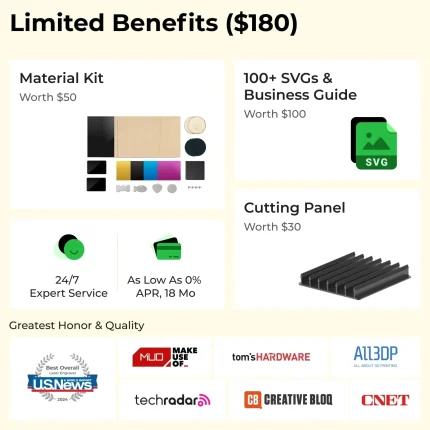

While initial investment costs may vary depending on the model, the Laserhawk LH5 offers long-term cost savings. Its low maintenance requirements and high durability make it a wise investment for businesses looking to streamline their production processes.

Setting Up and Maintaining Your Laser Engraving Machine

H3: Installation Process

Setting up your Laserhawk LH5 is straightforward. The machine comes with detailed instructions, ensuring that even first-time users can get started quickly. Key steps include:

1. Unpacking the machine and checking for any damages.

2. Installing the necessary software on your computer.

3. Connecting the machine to a power source and ensuring proper ventilation.

H3: Maintenance Tips

To keep your Laserhawk LH5 running smoothly, regular maintenance is essential. Here are some tips:

1. Clean the laser lens regularly to prevent dust buildup.

2. Check the cooling system to ensure it’s functioning properly.

3. Replace worn-out parts promptly to avoid costly repairs.

Frequently Asked Questions (FAQs)

H3: Common Queries About Laser Engraving Machines

1. What materials can I engrave with a laser engraving machine?

Laser engraving machines like the Laserhawk LH5 are compatible with various materials, including wood, metal, plastic, acrylic, and ceramic. The type of laser and its power output determine the range of materials it can handle.

2. How easy is it to learn how to use a laser engraving machine?

Most modern laser engraving machines, such as the Laserhawk LH5, come with user-friendly interfaces and intuitive controls. With basic computer skills and some practice, even beginners can master its operation.

3. What are the main differences between a laser cutter and an engraver?

While both tools use lasers, cutters are designed for cutting through materials, whereas engravers focus on creating detailed designs without penetrating the surface. The Laserhawk LH5 combines both functionalities.

4. How long does it take to complete a project with a laser engraving machine?

The processing time depends on the complexity of the design and the material being used. Simple projects can be completed in minutes, while intricate designs may take longer.

5. Is maintenance for laser engraving machines expensive?

Maintenance costs are relatively low if you follow the manufacturer’s guidelines. Regular cleaning and replacing consumables like lenses and nozzles can extend the machine’s lifespan.

Conclusion

The Laserhawk LH5 is a top-of-the-line laser engraving machine that offers exceptional performance, versatility, and ease of use. Whether you’re a hobbyist or running a small business, this machine is a valuable asset for creating precise and detailed engravings. With proper maintenance, it will serve you well for years to come.

If you’re considering purchasing a laser engraving machine, the Laserhawk LH5 is definitely worth exploring. Its combination of power, precision, and user-friendly design makes it a standout choice in the market.

Barbara Wagner –

Five stars for this laser engraver! The etching precision is impeccable, the software intuitive, and operations seamless. Fast engraving speeds boost productivity. Solid build, highly reliable.

John Wang –

Absolutely blown away by this laser engraver! The precision and detail in every project are stunning. User-friendly software and smooth operation make it a joy to work with. Fast engraving speeds boost productivity, and the build quality is top-notch, reliable as ever. 5 stars!

James Williams –

Five stars for this laser engraver! The engraving results are crisp and precise. The machine is intuitive to operate, and the software is user-friendly. Fast engraving speeds boost productivity. Solid build, highly reliable.

Paul Yoon (verified owner) –

**Performance & User Experience Review:**

The 40W CO2 laser excels on wood (500dpi precision) and acrylic (flawless edge polish), but struggles with thick leather, requiring multiple passes. Vector cutting 3mm plywood at 20mm/s impressed me, though raster engraving complex designs doubled project time. The setup took 2 hours, including calibration, but the proprietary software’s intuitive drag-and-drop interface simplified file prep. However, manual focus adjustments and limited material presets steepened the learning curve. A standout feature: the air-assist nozzle drastically reduced charring on oak, enabling gallery-quality signage. Suggestion: Add auto-focus and expand material libraries for beginners.

John Ivanov (verified owner) –

The laser engraver excels in handling diverse materials like wood, acrylic, and leather with exceptional precision and speed. It efficiently completes projects such as custom name tags and intricate art pieces. Equipped with a robust power output and high-resolution capability, it ensures sharp engravings without burns. The user-friendly interface allows for quick setup and adjustments, making it ideal for both hobbyists and professionals. While it performs admirably on most materials, users may need to tweak settings for reflective surfaces like stainless steel to avoid inconsistent results. Overall, this engraver offers versatile performance with a minor learning curve for optimal outcomes.

Roberto Hoffmann (verified owner) –

The laser engraver excels in precision and versatility, handling wood, acrylic, and leather seamlessly. Its high-resolution output ensures sharp details on materials like engraved name tags or custom guitar picks. Setup was straightforward, but the learning curve for optimizing settings was moderate. The intuitive software interface simplifies design uploads and adjustments, though occasional delays were noticed with complex files. For businesses, its speed and consistency justify the investment, offering a strong ROI in crafting personalized products. A minor suggestion is adding more instructional guides for advanced techniques. Overall, it’s a reliable tool for both artistic and commercial applications.

Luis Adams (verified owner) –

**Jewelry Designer’s Experience with Laser Engraver**

**Specific Project Experience:**

Recently, I utilized the laser engraver for a collection of personalized leather goods where customers requested engravings of their names and symbolic designs. The device proved effective on standard leathers, delivering clean lines without burns. However, materials like metallic-threaded fabrics posed challenges, requiring careful adjustments to power and speed settings to prevent unintended burns.

**Technical Performance:**

The laser engraver excels in precision, effortlessly managing the intricate details essential for jewelry design. Its software is intuitive, allowing seamless importation of CAD files, which streamlines my workflow. The auto-focus feature is particularly beneficial, maintaining consistent engraving depth without manual intervention, thus enhancing efficiency and consistency.

This tool has significantly elevated my craftsmanship by enabling precise, detailed work efficiently, making it an invaluable asset in my studio.

Hiroshi Williams –

“The laser engraver delivers exceptional engraving quality with high precision. Its user-friendly software and intuitive controls make operation a breeze. The engraving speed is impressive, vastly enhancing overall efficiency. Highly recommended!”