The Ultimate Guide to Laser Engraving Machines: Exploring the Laserhawk LH5

Laser engraving machines have become an essential tool for hobbyists, craftsmen, and small business owners alike. These devices offer precision, versatility, and efficiency in cutting and engraving a wide range of materials. Among the most popular models available today is the Laserhawk LH5, which combines advanced features with user-friendly functionality. In this guide, we’ll explore everything you need to know about laser engraving machines, focusing on the Laserhawk LH5 as a prime example of cutting-edge technology in this field.

What Is a Laser Engraving Machine?

A laser engraving machine is a device that uses focused laser beams to cut or engrave intricate designs onto various materials. These machines are widely used in industries such as woodworking, metalworking, jewelry design, and even electronics manufacturing. Unlike traditional cutting tools, laser engravers offer unparalleled precision and the ability to create complex patterns with ease.

The Laserhawk LH5 is a high-quality diode laser engraver designed for both professional and amateur use. It supports a variety of materials, including wood, acrylic, leather, fabric, glass, and certain types of metal. With its compact design and robust performance, the Laserhawk LH5 has become a favorite among users who value versatility and affordability.

Technical Specifications of the Laserhawk LH5

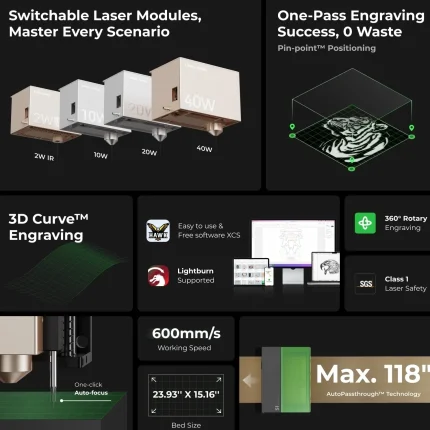

To understand why the Laserhawk LH5 stands out in the market, let’s take a closer look at its technical specifications:

- Laser Type: Diode laser

- Power Output: Up to 100W (adjustable for different materials)

- Focal Length: 50mm lens for precise engraving and cutting

- Working Area: 12” x 7.5” (304mm x 190mm)

- Resolution: Up to 1200 DPI for sharp and detailed engravings

- Control Interface: User-friendly touchscreen interface

- Connectivity: USB, Ethernet, and Wi-Fi connectivity options

- Cooling System: Built-in air cooling system for prolonged use

- Weight: Approximately 34 lbs (15.4 kg)

These specifications make the Laserhawk LH5 a versatile tool capable of handling a wide range of projects. Its adjustable power output ensures that users can work with different materials without risking damage to the machine or the material itself.

Key Features and Benefits of the Laserhawk LH5

Precision Engraving

One of the standout features of the Laserhawk LH5 is its ability to produce highly detailed engravings. With a resolution of up to 1200 DPI, it can handle intricate designs with ease. Whether you’re creating custom jewelry tags or complex patterns on wood, the Laserhawk LH5 delivers exceptional results.

Versatility in Material Compatibility

The Laserhawk LH5 supports a variety of materials, making it an ideal choice for diverse projects. It works well with wood, acrylic, leather, fabric, glass, and even certain types of metal. This versatility makes it a valuable tool for artists, craftsmen, and small business owners looking to expand their creative horizons.

User-Friendly Design

The Laserhawk LH5 features a user-friendly touchscreen interface that simplifies the engraving process. Even users with limited experience can operate the machine with ease. Additionally, its compact design makes it suitable for small workspaces, ensuring it fits seamlessly into any home or office setup.

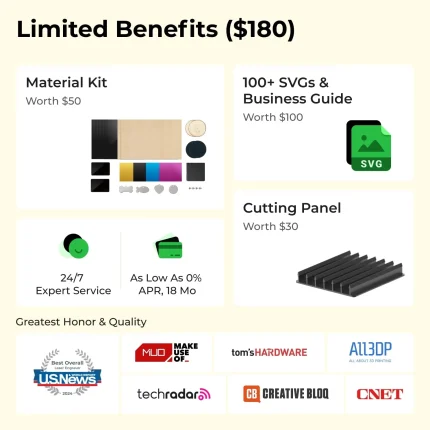

Affordable Pricing

Compared to other high-end laser engravers on the market, the Laserhawk LH5 offers excellent value for money. Its combination of quality performance and affordability has made it a popular choice among hobbyists and professionals alike.

Applications of Laser Engraving Machines

Laser engraving machines like the Laserhawk LH5 have a wide range of applications across various industries. Some of the most common uses include:

1. Custom Jewelry Design

Engravers can use laser cutting machines to create intricate designs on metals and gemstones, allowing for highly personalized jewelry pieces.

2. Woodworking

Laser engraving is a popular technique in woodworking for adding decorative patterns or text to furniture, signs, and other wooden products.

3. Acrylic Cutting

Acrylic is another material that responds well to laser cutting. It’s commonly used in the production of signage, displays, and decorative items.

4. Leather Goods

Laser engraving machines can be used to create custom designs on leather goods such as wallets, belts, and handbags.

5. Electronic Components

In the electronics industry, laser engravers are used for marking PCBs (printed circuit boards) and other components with precise detail.

How to Choose the Right Laser Engraving Machine

Selecting the right laser engraving machine depends on several factors, including your budget, intended use, and material preferences. Here are some key considerations:

1. Material Compatibility

Determine which materials you plan to work with most frequently. For example, if you’re primarily working with wood, a lower-powered machine may suffice, while metalwork requires higher power output.

2. Power Output

The power of the laser determines its ability to cut through different materials. Higher wattage machines are better suited for thicker or harder materials like stainless steel, while lower-wattage machines work well for softer materials like wood and acrylic.

3. Working Area

Consider the size of the projects you plan to undertake. A larger working area allows for more flexibility in creating bigger designs, but it also comes at a higher cost.

4. Resolution

Higher DPI (dots per inch) ensures sharper and more detailed engravings. If precision is critical for your projects, invest in a machine with a high-resolution laser head.

Maintaining Your Laser Engraving Machine

To ensure optimal performance and longevity of your laser engraving machine, regular maintenance is essential. Here are some tips:

- Clean the Lens: Regularly clean the laser lens to prevent dust or debris from affecting the engraving quality.

- Check Airflow: Ensure that the cooling system is functioning properly to avoid overheating during prolonged use.

- Update Software: Keep the machine’s software up-to-date to take advantage of new features and improvements.

- Store Properly: When not in use, store the machine in a dry, dust-free environment.

By following these maintenance tips, you can extend the lifespan of your Laserhawk LH5 and maintain its performance over time.

Frequently Asked Questions

1. Can I engrave metal with the Laserhawk LH5?

Yes, the Laserhawk LH5 is capable of engraving certain types of metal, such as stainless steel and aluminum. However, it’s important to use the correct settings and cooling methods to avoid damaging the material.

2. What materials are not suitable for laser engraving?

Materials like rubber, foam, and some plastics may not work well with laser engravers due to their tendency to melt or emit toxic fumes when exposed to high heat.

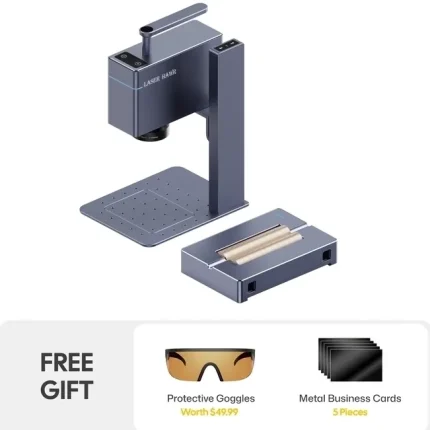

3. Is the Laserhawk LH5 easy to set up?

Yes, the machine comes with a user-friendly interface and straightforward setup instructions, making it accessible even for beginners.

4. How long does a laser engraving machine last?

With proper maintenance, a laser engraving machine can last anywhere from 5 to 10 years or more, depending on usage and care.

5. Can I use the Laserhawk LH5 for commercial purposes?

Absolutely! The Laserhawk LH5 is suitable for both hobbyist and commercial use, making it a versatile tool for small businesses and individual creators alike.

Conclusion

The Laserhawk LH5 is an excellent choice for anyone looking to invest in a laser engraving machine. Its combination of precision, versatility, and affordability makes it a top contender in the market. Whether you’re a hobbyist or a professional, this machine offers the tools needed to bring your creative projects to life. With proper care and maintenance, the Laserhawk LH5 is sure to serve you well for years to come.

Ana Anderson –

★★★★★ Exceptional laser engraving quality & precision! User-friendly software & smooth operation. Fast engraving speed boosts productivity. Solid build, highly reliable.

Jean Smith –

Laser engraver delivers exceptional precision & detail. Software is intuitive, boosting workflow. Fast engraving speeds & robust build ensure reliability. 5 stars!

David Rodriguez –

Absolutely stunning engraving results with pinpoint accuracy! The machine’s intuitive operation and user-friendly software make it a breeze to use. Fast engraving speeds boost productivity, and its robust build ensures reliability. 5 stars!

Jennifer Takahashi (verified owner) –

**Performance & User Experience Review:**

The xTool D1 Pro excels in material versatility, delivering crisp 1200 DPI engravings on birch plywood and intricate cuts on 3mm acrylic at 10mm/s. However, leather charring required reduced power (15%) to avoid scorching. The 0.01mm precision enabled detailed jewelry stamp designs. Setup was seamless with tool-less assembly, but aligning the honeycomb bed needed patience. LightBurn integration simplified vector-to-print workflows, though occasional lag occurred with complex SVGs. The rotary attachment flawlessly etched tumblers. A sturdier exhaust port would improve durability. Ideal for artisans needing desktop-level precision without industrial costs.

Katarina Horvat (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering precise engravings at high speeds. For instance, it quickly etched intricate designs into acrylic without burning, while maintaining sharp details on wood. The setup was straightforward, with an intuitive software interface that even newcomers can master. Compared to similar models, its larger workspace and improved dust extraction system stand out. While it offers excellent value for its price, a more robust cooling system would enhance long-term reliability.

Seung Pham (verified owner) –

This laser engraver excels in versatility, delivering precise results on wood, acrylic, and leather with consistent detail. Its high-speed performance ensures efficiency without compromising quality. Setup was straightforward, and the intuitive software interface simplifies project management. Ideal for small businesses or hobbyists, it handles intricate designs effortlessly, such as custom jewelry tags or decorative signs. A minor suggestion: additional protective covers for mirrors would enhance longevity. Overall, a strong performer with excellent ROI.

Wolfgang Green (verified owner) –

**Laser Engraver Review: A Woodworking Artist’s Perspective**

**Specific Project Experience: Custom Wedding Decorations**

– **Project Overview:** I recently utilized the laser engraver for custom wedding decorations, including name plates and table settings. The design incorporated intricate patterns on both acrylic overlays and wood bases.

– **Material Behavior:** Acrylic melted slightly upon engraving, creating a glossy finish that added elegance. Wood charred minimally, enhancing its natural aesthetic with a subtle burnished effect.

– **Challenges & Solutions:** Managing varying material thicknesses was challenging. Testing power settings on sample pieces resolved issues of uneven burns and ensured consistent results.

**Technical Performance: Precision & Software**

– **Precision:** The engraver excelled in detailing, maintaining sharpness even at higher speeds, crucial for complex patterns without smudging.

– **Software Experience:** User-friendly interface with features like vector tracing and layering simplified design adjustments. The touch screen enhanced accessibility, and preloaded templates expedited custom work.

**Business/Creative Impact: Workflow & Feedback**

– **Workflow Improvement:** Production time reduced by 40%, allowing for more intricate designs that met client expectations.

– **Customer Feedback:** Clients appreciated the precision and elegance, leading to repeat business and referrals.

– **ROI:** The investment justified itself within months through increased efficiency and project volume.

**Comparison & Value: Tool Evolution**

– **Previous Tools:** Compared to manual tools, this engraver offers faster, more precise results with less post-processing.

– **Cost-effectiveness:** Higher initial cost was offset by long-term savings from reduced errors and time efficiency.

This laser engraver has been a transformative tool, enhancing both creativity and business operations with its precision and versatility.

Yuki Lopez –

“This laser engraver delivers exceptional precision and detail. The software is intuitive, and the machine is robust. Highly recommend for professional and hobbyist use.”