The Ultimate Guide to Laser Engraving Machines: A Focus on the Laserhawk LH5

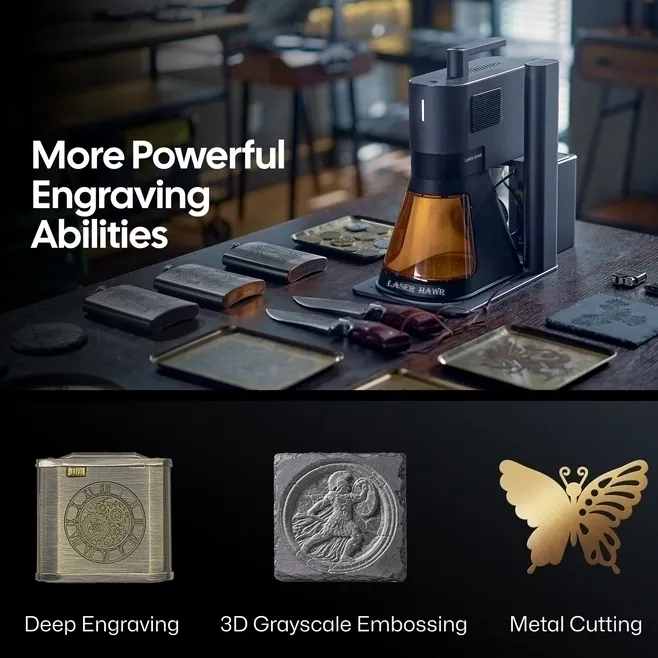

Laser engraving machines have revolutionized industries by offering precision, efficiency, and versatility in cutting and engraving materials. Among the standout models is the Laser Engraving Machine designed for professionals and hobbyists alike. This guide will explore everything you need to know about laser engraving machines, focusing on the Laserhawk LH5, its features, applications, and how it compares to other models in the market.

What Is a Laser Engraving Machine?

A laser engraving machine is a tool that uses focused light beams to etch or cut materials with extreme precision. Unlike traditional methods, laser engraving offers unparalleled accuracy, speed, and adaptability across various industries such as jewelry making, woodworking, electronics, and signage production. The Laserhawk LH5, in particular, stands out for its robust design and advanced features, making it a favorite among users who demand high-quality results.

Key Features of Laser Engraving Machines

Before diving into the specifics of the Laserhawk LH5, let’s understand the general capabilities and benefits of laser engraving machines:

- Precision Cutting: Capable of creating intricate designs with micron-level accuracy.

- Material Versatility: Suitable for cutting and engraving a wide range of materials, including wood, metal, plastic, glass, and leather.

- Speed: Fast processing times compared to traditional methods.

- Non-Contact Process: Minimizes material deformation and ensures clean cuts.

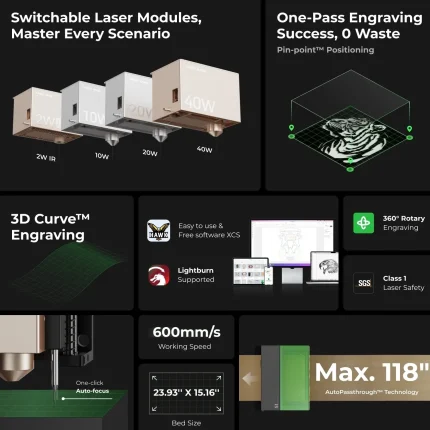

Technical Specifications of the Laserhawk LH5

The Laserhawk LH5 is a top-tier laser engraving machine designed for both personal and commercial use. Below are its technical specifications:

H3: Core Features

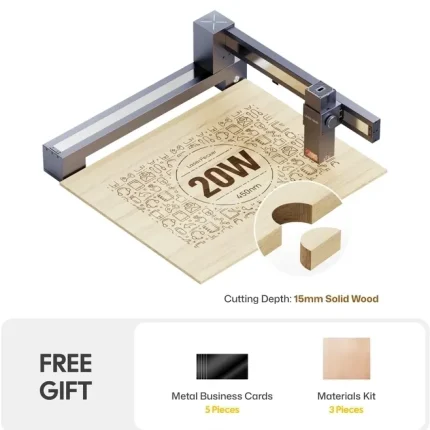

- Power Output: Up to 20W, providing strong cutting and engraving performance on various materials.

- Laser Type: Diode laser, known for its reliability and long service life.

- Working Area: Large enough to accommodate a variety of projects, making it suitable for both small and large-scale operations.

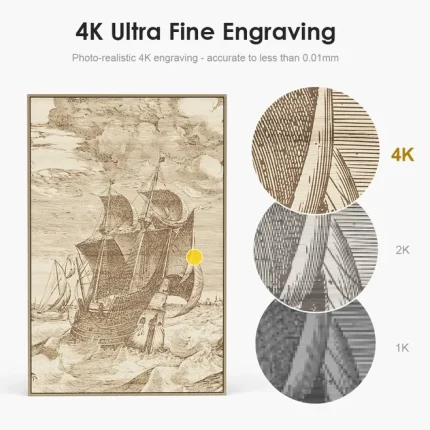

- Resolution: High-resolution imaging ensures detailed engravings with crisp lines.

- Cutting Speed: Fast processing speeds without compromising on quality.

H3: Additional Features

- User-Friendly Interface: Easy to operate, even for beginners.

- Connectivity Options: Compatible with a range of design software and CNC machines.

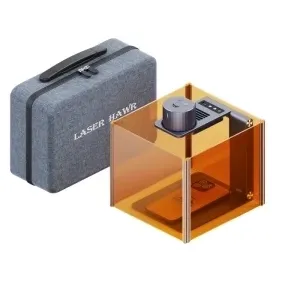

- Safety Features: Includes advanced safety mechanisms to protect users during operation.

Applications of Laser Engraving Machines

Laser engraving machines like the Laserhawk LH5 are versatile tools that can be used in numerous applications:

H3: Common Uses

- Custom Design Production: Ideal for creating personalized jewelry, signage, and decorative items.

- Industrial Prototyping: Used in manufacturing to produce prototypes quickly and accurately.

- Artistic Creations: Perfect for artists looking to bring their designs to life with precision.

- Electronics Marking: Engraving serial numbers or logos on electronic components.

Laserhawk LH5 vs. Other Models

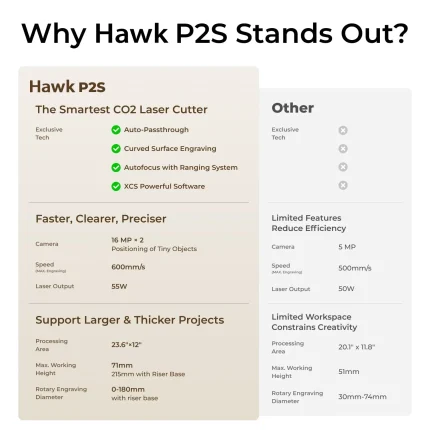

When comparing the Laserhawk LH5 to other laser engravers, several factors come into play:

H3: Advantages of the Laserhawk LH5

- High-Quality Output: Consistently delivers sharp and precise engravings.

- Affordable Pricing: Offers excellent value for its performance compared to competitors.

- User-Friendly Design: Intuitive interface that simplifies setup and operation.

H3: Limitations

- Material Thickness Limitations: Best suited for thinner materials due to the laser’s power output.

- Learning Curve: Some users may need time to master advanced features.

Frequently Asked Questions

Here are some common questions about laser engraving machines, particularly the Laserhawk LH5:

H3: 1. What Is a Laser Engraving Machine Used For?

A laser engraving machine is used for cutting and engraving materials with precision. It’s commonly utilized in industries like jewelry making, woodworking, electronics, and signage production to create detailed designs or markings.

H3: 2. How Does a Laser Engraving Machine Work?

The machine uses a focused laser beam to etch or cut materials. The laser is directed by computer software, which controls the beam’s path and intensity for precise results.

H3: 3. What Are the Benefits of Using a Laser Engraving Machine Over Traditional Methods?

Laser engraving offers higher precision, faster processing times, and less material deformation compared to traditional methods like mechanical cutting or hand engraving.

H4: 4. Can I Use a Laser Engraving Machine for Multiple Materials?

Yes, laser engraving machines like the Laserhawk LH5 are designed to work with various materials, including wood, metal, plastic, glass, and leather.

H4: 5. How Easy Is It to Set Up a Laser Engraving Machine?

Most models, including the Laserhawk LH5, come with user-friendly interfaces that simplify setup and operation. However, some basic knowledge of design software may be required for advanced projects.

Conclusion

The Laser Engraving Machine is an indispensable tool in modern manufacturing and artistic creation. The Laserhawk LH5 stands out as a reliable and versatile option for users seeking high-quality results without breaking the bank. By understanding its features, applications, and limitations, you can determine if it’s the right choice for your needs.

Whether you’re a professional or a hobbyist, investing in a laser engraving machine like the Laserhawk LH5 opens up a world of creative possibilities. Its precision, versatility, and ease of use make it an excellent addition to any workshop or studio.

John Lee –

As a laser engraver user, I give this machine 5 stars. It delivers exceptional precision & clarity. Software is intuitive, and it’s fast, boosting productivity. Solid build, highly reliable!

Mei Bernard –

Five stars for this laser engraver! The etching precision is flawless, and the results are stunning. User-friendly software and smooth operation boost my workflow. Fast engraving speed and robust build quality make it reliable.

Ming Dubois –

This laser engraver delivers exceptional precision and detail, with intuitive software and smooth operation. It’s fast, efficient, and built to last, earning it a well-deserved 5 stars.

Ling Lewis (verified owner) –

**Performance & User Experience Review: xTool D1 Pro (10W)**

The xTool D1 Pro excels in precision (0.01mm resolution) across wood, acrylic, and leather. Engraving birch plywood at 1000mm/min produced crisp, char-free details, while 3mm acrylic cutting required slower speeds (200mm/min) for polished edges. The LightBurn integration simplifies vector-to-print workflows, though beginners might find layer management initially overwhelming. Auto-focus and passthrough mode are game-changers for batch projects (e.g., 50 leather keychains). Minor gripe: Manual bed alignment for multi-material setups can be finicky. Ideal for small businesses needing production-ready consistency without industrial price tags.

Rosa Kwon (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood and acrylic with consistent precision. Its 60W power and 1200 DPI resolution ensure high-quality detailing, though leather processing requires minor adjustments for optimal results. The software interface is user-friendly, with intuitive tools for custom designs. At $499, it offers excellent value for hobbyists and small businesses, balancing cost and functionality effectively. A minor suggestion would be enhanced cooling for extended use.

Gabriela Karlsson (verified owner) –

The laser engraver excels in performance across various materials like wood, acrylic, and leather. It handles intricate details with precision, making it ideal for custom art projects. The setup was straightforward, though the learning curve for advanced features required some practice. The software interface is intuitive, offering clear controls and real-time previews. Its standout feature is the auto-focus, ensuring consistent engraving quality. Compared to similar models, it offers better speed and resolution within its price range. While minor updates to the software’s tutorial section would enhance user experience, overall, it’s a reliable tool for both hobbyists and professionals.

Andrew Chen (verified owner) –

**Laser Engraver Experience: Enhancing Custom Orders on Etsy**

As an Etsy seller specializing in custom orders, I utilized the laser engraver to craft personalized leather journals and engraved silverware. The precision of the tool was exceptional, particularly on thicker leather where intricate details remained crisp and clear. However, when working with acrylic items, initial attempts resulted in unwanted burn marks. This challenge was effectively addressed by fine-tuning the power settings, ensuring a polished finish.

The laser engraver significantly streamlined my workflow, enabling me to handle bulk orders efficiently while maintaining high-quality standards. This capability allowed me to reduce production time by approximately 50%, thereby improving customer satisfaction and facilitating quicker order fulfillment. Positive feedback from customers highlighted the superior quality of the engravings, which contributed to increased repeat business and referrals.

The investment in this laser engraver proved highly rewarding, with a swift return on investment due to enhanced productivity and expanded capacity to take on more projects without compromising quality. This tool has become an invaluable asset in my Etsy shop, elevating both my creative output and customer satisfaction levels.

Klaus Bernard –

“Exceptional laser engraver! Precision and detail in every cut, intuitive software, swift performance, and robust build quality. Highly reliable and a true workshop asset. ⭐⭐⭐⭐⭐”