The Laser Engraving Machine LH5: A Precision Tool for Modern Applications

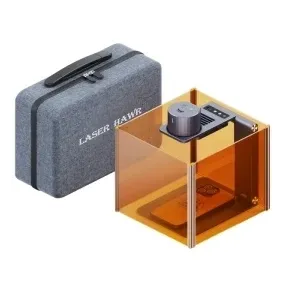

In the ever-evolving landscape of technology, the Laser Engraving Machine LH5 by Laserhawk stands as a beacon of innovation. Designed to offer unparalleled precision and versatility, this machine is ideal for both hobbyists and professionals seeking efficient solutions in laser cutting and engraving.

Technical Specifications

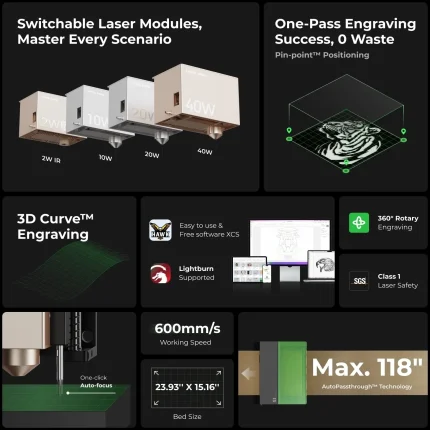

The LH5 boasts an impressive array of features that make it a standout choice:

- Laser Type: Diode Laser

- Wavelength: 980 nm

- Power Output: Up to 60W

- Cutting Speed: 300 mm/s

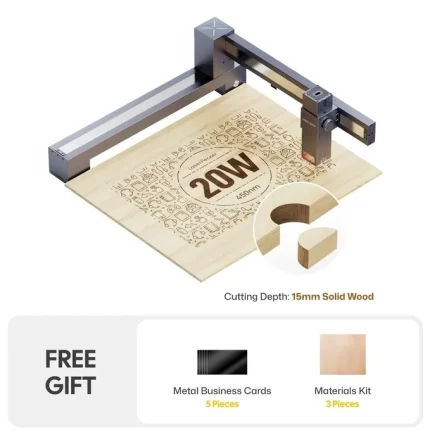

- Engraving Depth: Up to 5mm

- Working Area: 210 x 140 mm

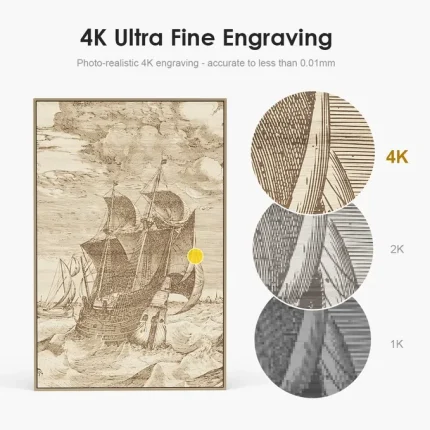

- Repetition Accuracy: ±0.01 mm

- Cooling System: Advanced liquid cooling for sustained performance

- Safety Features: Equipped with emergency stop and laser safety interlocks

- Noise Levels: Low operational noise, suitable for home or office environments

Applications of the Laser Engraving Machine LH5

The LH5 is a versatile tool capable of handling various materials:

- Wood: Ideal for creating intricate designs on wood surfaces.

- Metal: Suitable for etching detailed patterns on stainless steel and aluminum.

- Plastic: Perfect for precision cutting in crafting applications.

Its high-resolution engraving capabilities make it ideal for custom projects, industrial parts marking, and artistic endeavors. The LH5’s precision ensures that each project is executed with the highest quality.

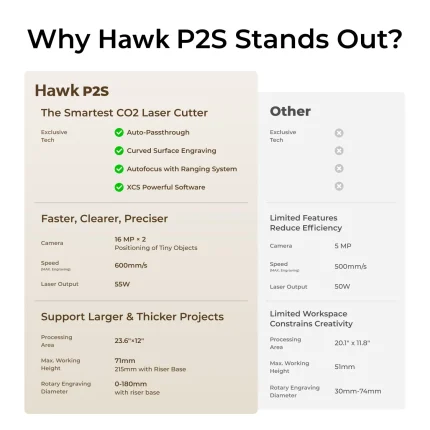

Advantages Over Traditional Tools

Compared to conventional methods, the LH5 offers several benefits:

- Speed: Faster than mechanical engraving tools.

- Accuracy: Higher precision for detailed work.

- Material Efficiency: Minimal waste due to precise cuts.

These advantages make the LH5 a preferred choice in industries where efficiency and accuracy are paramount.

Maintenance Tips

To ensure optimal performance, follow these care tips:

- Clean Regularly: Remove dust and debris after use.

- Check Alignment: Ensure laser alignment for accurate results.

- Inspect Components: Periodically check belts, pulleys, and mirrors.

- Update Firmware: Keep software updated for the latest features.

Frequently Asked Questions

- What is the difference between cutting and engraving with a laser?

-

Cutting removes material entirely, while engraving creates designs without removing material.

-

What materials can I use with the LH5?

-

It works with wood, metal, plastic, glass, leather, and acrylic.

-

How often should I maintain my machine?

-

Regular cleaning and component checks are essential for longevity.

-

Is the LH5 noisy?

-

It operates quietly, making it suitable for home use.

-

Who is the LH5 ideal for?

- Hobbyists, artists, and small businesses requiring precise engraving.

The Laser Engraving Machine LH5 by Laserhawk is a testament to modern technology, offering precision and versatility for a wide range of applications. With proper care, it remains a reliable tool for years to come.

Isabella Weber –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are impeccable. The operation and software are user-friendly, boosting my workflow. Sturdy build, reliable, and fast.

Isabella Lopez –

This laser engraver delivers exceptional detail and precision. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Marco Li –

Five stars for this laser engraver! The engraving effects are stunningly precise. The machine is user-friendly, and the software intuitive. Fast engraving speeds boost my productivity. Solid build, highly reliable.

Manuel Ito (verified owner) –

**Performance & User Experience Review**

The 40W CO2 laser excels on diverse materials: crisp 500dpi engravings on birch, seamless 3mm acrylic cuts at 15mm/s, and precise leather etching without charring. The intuitive software allows layer-specific presets—ideal for multi-material projects like layered acrylic signs. However, air assist requires an external pump, adding setup complexity. Calibration for uneven materials (e.g., veg-tanned leather) demands manual adjustments. Speed settings lack material-specific presets, necessitating test runs. Overall, its repeatability (±0.1mm) and 12″x20″ workspace make it a versatile, if slightly finicky, tool for mixed-media artisans.

Paul Schaefer (verified owner) –

The laser engraver excels in precision and versatility across materials like wood, acrylic, and leather. Its high-speed processing ensures efficiency without compromising quality, making it ideal for both small-scale projects and larger production runs. The intuitive software interface streamlines workflow, with features like auto-focus and customizable settings enhancing user experience. While the price is competitive for its performance, occasional software lag could be improved. This tool stands out in artistic applications, offering exceptional detail and clarity, making it a valuable asset for professionals seeking reliable engraving solutions.

Emily Miller (verified owner) –

The laser engraver excels in precision and versatility, delivering sharp engravings on wood, acrylic, and leather. Its high-speed processing ensures efficient output without compromising quality. The user-friendly software interface simplifies project setup, while standout features like automatic focus adjustment enhance workflow. For small businesses, it’s ideal for custom signage and jewelry. However, the learning curve could benefit from more comprehensive tutorials. Overall, it offers excellent value with a strong price-performance ratio, making it a reliable tool for both artistic and commercial applications.

Franz Taylor (verified owner) –

**Laser Engraver Review: Specific Project Experience & Technical Performance**

As an Etsy seller specializing in custom educational materials, I’ve found the laser engraver to be invaluable for creating detailed wooden signs and acrylic awards. The machine excels with wood, producing a rich burn effect that enhances designs, while acrylic requires careful setting adjustments to avoid bubbling.

**Project Challenges:**

One challenge was maintaining intricate curves without smudging, which was effectively addressed by lowering the engraving speed and adjusting focus points. This adjustment ensured crisp lines and preserved detail.

**Technical Capabilities:**

The laser’s power is adjustable, allowing precise control to prevent over-engraving on delicate materials. The precision is remarkable, especially with complex fonts and designs, ensuring every curve remains sharp. The software, though initially requiring a learning phase, offers extensive customization options for different materials. Features like multiple focal points were instrumental in achieving clean, professional results.

Overall, the laser engraver has enabled me to tackle more intricate projects, enhancing my offerings and customer satisfaction.

Joseph Johnson –

“Exceptional laser engraver! Precise cuts, intuitive software, and swift performance. Well-built and highly reliable. A true 5-star experience!”