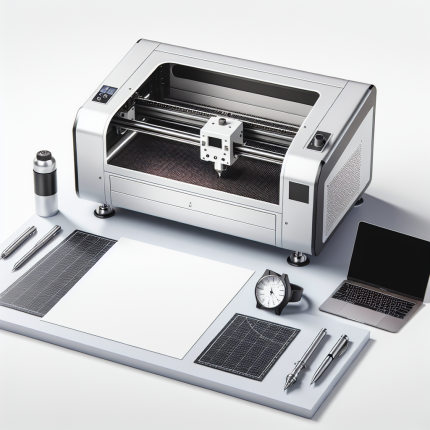

Understanding Laser Engraving Machines: A Comprehensive Guide

Laser engraving machines have revolutionized the way we create intricate designs on various materials. These devices use high-powered lasers to etch or cut surfaces with precision, offering a modern alternative to traditional methods. If you’re new to this technology, this guide will provide an in-depth look at how laser engraving machines work, their technical specifications, and applications across different industries.

How Laser Engraving Machines Work

Laser engraving machines operate by directing a focused beam of light onto the surface of a material. This process involves several steps:

- Material Interaction: The laser beam interacts with the material, causing localized melting, vaporization, or discoloration to create the desired design.

- Precision Control: Advanced control systems ensure that each engraving is precise and consistent, making these machines ideal for industrial applications where accuracy is critical.

Technical Specifications of Laser Engraving Machines

When considering a laser engraving machine, understanding its technical specifications is crucial. Here are key features to look for:

- Laser Type: Common types include CO2 and fiber lasers, each suited for different materials.

- Power Output: Typically ranges from 10W to 100W, affecting the speed and depth of engraving.

- Repetition Rate: Higher rates enable faster processing, ideal for large-scale production.

- Beam Quality: Assessed by M² parameter; lower values indicate better focusability.

- Software Compatibility: Most machines work with CAD/CAM software, allowing complex designs.

- Optional Accessories: Include air assist systems and vacuum tables for material holding.

Applications Across Industries

Laser engraving finds application in various sectors due to its versatility:

Industrial Manufacturing

Used for marking parts with serial numbers or logos, enhancing traceability and brand presence.

Jewelry Design

Engravers create detailed patterns on precious metals and stones, offering a unique touch to each piece.

Signage Production

Ideal for creating custom signs with high-quality text and graphics, suitable for both indoor and outdoor use.

Benefits and Limitations

Benefits:

– Precision: Achieve intricate details impossible with traditional methods.

– Speed: Fast processing times reduce production cycles.

– Material Compatibility: Works on metals, plastics, wood, glass, and more.

Limitations:

– Cost: Higher initial investment compared to other engraving tools.

– Maintenance: Regular servicing is necessary to maintain performance.

Conclusion

Laser engraving machines offer a blend of precision, speed, and versatility, making them indispensable in various industries. As technology advances, these machines are likely to become even more efficient, opening new possibilities for creative and industrial applications.

FAQ Section

- What’s the difference between laser marking and engraving?

-

Laser marking leaves a surface layer while engraving removes material for deeper cuts.

-

Which laser type is best for metals?

-

Fiber lasers are preferred for their efficiency on metal surfaces.

-

How often should I maintain my machine?

-

Regular cleaning of optics and checking gas levels are essential for optimal performance.

-

What affects the cost of a laser engraver?

-

Factors include power output, type (CO2 vs. fiber), and additional features.

-

Why choose laser over traditional methods?

- Offers higher precision, speed, and the ability to work on diverse materials.

This guide aims to provide a thorough understanding of laser engraving machines, helping you make informed decisions for your projects.

Carol Gonzalez (verified owner) –

This laser engraver excels in precision and versatility, seamlessly handling wood, acrylic, and leather. Its high-speed performance ensures efficient processing of intricate designs, such as custom wooden name tags and detailed acrylic signs. The intuitive software interface simplifies setup and design customization, with a drag-and-drop feature that streamlines workflow. However, occasional slow processing on complex acrylic projects could be improved. Overall, it’s a reliable tool for both artistic and business applications, offering exceptional value for its performance capabilities.

Hana Kim (verified owner) –

The laser engraver excels across various materials, delivering precise engravings on wood with intricate designs, acrylic with clean cuts, and leather showing consistent results. The high power setting ensures darker markings on wood, while lower settings prevent burns on acrylic. Its 1200 DPI resolution enhances detail clarity. The workspace dimensions allow for medium-sized projects, accommodating diverse tasks efficiently. A minor suggestion is an adjustable bed for added durability in heavy-duty applications, enhancing long-term usability without compromising performance.

Sophie Ito (verified owner) –

**Laser Engraver Review: An Art Teacher’s Perspective**

**Introduction:**

As an art teacher, integrating technology into my projects has been transformative. My experience with the laser engraver has significantly enhanced both my teaching methods and students’ learning experiences.

**Specific Project Experience:**

One standout project was creating custom USB drives and engraved coasters for a local business promotion. Using materials like acrylic and wood, I observed how each reacted differently under the laser. Acrylic provided vibrant engravings but required careful power adjustments to prevent warping. Wood offered a natural aesthetic but needed precise settings to avoid burn marks. The challenge was achieving consistent results across varying materials, which I addressed by experimenting with different power levels and speeds.

**Technical Performance:**

The laser engraver’s adjustable power settings were crucial in tackling the material variations. High precision allowed intricate designs, essential for detailed student art projects. The user-friendly software simplified design uploads, enabling even my students to create their own engravings. Features like air assist proved invaluable, reducing smoke and ensuring cleaner cuts. These technical capabilities not only streamlined our workflow but also elevated the quality of our final products.

**Conclusion:**

The laser engraver has been a game-changer in my studio. It combines versatility with precision, making it an indispensable tool for both educational and commercial projects. This investment has proven cost-effective and efficient, enhancing creativity and productivity alike.

Juan Li –

“Exceptional laser engraver! Precision is spot-on, software intuitive, and operation seamless. Fast, efficient, and built to last—a true workhorse. Highly recommend!”