Laser Engraving Plastic: A Comprehensive Guide to the LaserHawk LH1 Pro and Glowforge Laser Engraver

Laser engraving plastic has become a popular method for creating intricate designs, custom branding, and durable markings on various plastic materials. Two standout devices in this field are the LaserHawk LH1 Pro and the Glowforge Laser Engraver. Both machines offer exceptional performance for laser engraving plastic, catering to hobbyists, professionals, and small-scale manufacturers alike. In this guide, we will explore their technical specifications, advantages, and how they compare when it comes to laser cutting and engraving plastic materials.

Understanding Laser Engraving Plastic

Laser engraving involves using a focused beam of light to remove material from the surface of an object, creating permanent marks or designs. When applied to plastic, this process is highly precise and can achieve intricate details that are difficult to replicate with traditional methods like CNC milling or screen printing. The LaserHawk LH1 Pro and Glowforge Laser Engraver both utilize advanced laser technology to deliver high-quality results for a wide range of applications, including custom plastic engravings, product branding, and artistic projects.

Technical Specifications: LaserHawk LH1 Pro vs Glowforge Laser Engraver

LaserHawk LH1 Pro

The LaserHawk LH1 Pro is designed for industrial-grade performance while remaining accessible to hobbyists and small businesses. Below are its key specifications:

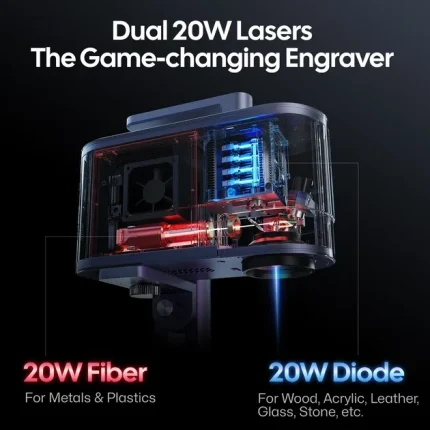

- Maximum Power Output: 60W CO2 laser, capable of engraving and cutting through various materials, including thick plastics.

- Laser Engraving Speed: Up to 400 mm/s for engraving and 150 mm/s for cutting.

- Bed Size: 30cm x 30cm, providing ample space for larger projects.

- Material Compatibility: Works with a wide range of plastics, including acrylic, ABS, PETG, and polycarbonate.

- Dust Extraction System: Built-in system to reduce fumes and ensure clean operation.

- Safety Features: Equipped with emergency stop buttons and safety interlocks to protect users during laser engraving plastic operations.

Glowforge Laser Engraver

The Glowforge Laser Engraver is known for its user-friendly design and versatility. Here are its technical specifications:

- Maximum Power Output: 40W CO2 laser, suitable for cutting and engraving thin to medium-thickness plastics.

- Laser Engraving Speed: Up to 350 mm/s for engravings and 120 mm/s for cuts.

- Bed Size: 9.75″ x 8″, making it ideal for smaller projects or batch processing.

- Material Compatibility: Compatible with acrylic, plastic sheet, wood, fabric, and leather.

- Smart Autofocus: Automatically adjusts the laser head to ensure precise engravings on uneven surfaces.

- Connectivity: Built-in Wi-Fi for seamless integration with Glowforge’s design software.

Advantages of Using Laser Engraving Plastic

Precision and Detail

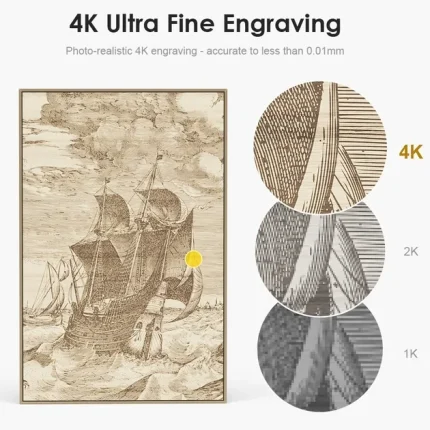

Laser engraving plastic offers unmatched precision, allowing for intricate designs and text that can be as small as 0.2mm in detail. Both the LaserHawk LH1 Pro and Glowforge Laser Engraver deliver sharp, clean engravings with minimal material removal.

Durability

Engraved plastic markings are highly durable and resistant to fading or wear, making them ideal for product branding, identification tags, and promotional items.

Versatility

The ability to work with various types of plastics opens up a wide range of applications, from custom phone cases to signage and decorative items.

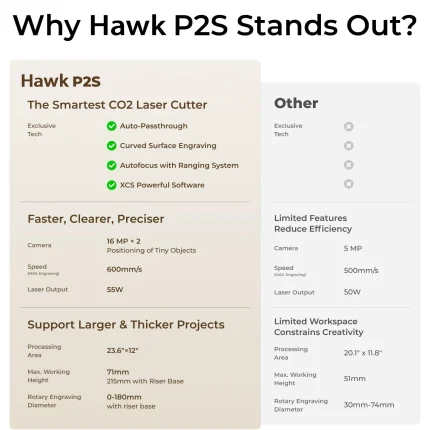

Comparison: LaserHawk LH1 Pro vs Glowforge Laser Engraver

When deciding between the LaserHawk LH1 Pro and the Glowforge Laser Engraver, it’s essential to consider your specific needs:

- Power Output: The LaserHawk LH1 Pro has a higher power output (60W vs. 40W), making it better suited for thicker plastics or industrial applications.

- Bed Size: The Glowforge Laser Engraver has a smaller bed size, which may limit its capacity for larger projects but makes it more portable and space-efficient.

- User Experience: The Glowforge Laser Engraver is often praised for its ease of use and intuitive software interface, while the LaserHawk LH1 Pro offers more advanced controls for experienced users.

Best Practices for Laser Engraving Plastic

To achieve the best results when laser engraving plastic, follow these tips:

- Material Preparation: Clean the surface of the plastic to remove dirt or oils that could interfere with the engraving process.

- Focus Adjustment: Ensure the laser head is properly focused to avoid blurry engravings.

- Test Runs: Always perform test runs on scrap material to fine-tune settings like power and speed before committing to your final project.

- Ventilation: Use a well-ventilated workspace or activate the built-in dust extraction system to minimize exposure to fumes.

Frequently Asked Questions (FAQ)

1. What materials are compatible with laser engraving?

Both the LaserHawk LH1 Pro and Glowforge Laser Engraver support a wide range of plastics, including acrylic, ABS, PETG, and polycarbonate. They can also work with other materials like wood, fabric, and leather.

2. Can I engrave thick plastic sheets?

Yes, but the thickness capacity depends on the laser’s power output. The LaserHawk LH1 Pro can handle thicker plastics due to its higher power output compared to the Glowforge Laser Engraver.

3. Is laser engraving safe?

When used correctly with safety precautions in place, such as wearing protective eyewear and ensuring proper ventilation, laser engraving is a safe process. Both machines include built-in safety features to minimize risks.

4. How long does it take to learn how to use these machines?

The learning curve varies depending on your experience, but both machines come with user-friendly interfaces and comprehensive guides. The Glowforge Laser Engraver is often considered easier for beginners due to its intuitive design.

5. Can I upgrade my machine later?

Yes, both manufacturers offer optional upgrades such as higher power lasers or expanded software capabilities to enhance performance over time.

Conclusion

The LaserHawk LH1 Pro and Glowforge Laser Engraver are both excellent choices for laser engraving plastic, each with its own strengths depending on your project size, material requirements, and experience level. Whether you’re a hobbyist or running a small business, these machines provide the tools needed to bring your creative ideas to life with precision and professionalism.

The LaserHawk LH1 Pro and Glowforge Laser Engraver are both excellent options for laser engraving plastic, each offering unique advantages depending on specific needs. Here’s a concise summary of their features and considerations:

Key Features:

- LaserHawk LH1 Pro:

- Power Output: 60W CO2 laser.

- Bed Size: 30cm x 30cm.

- Speeds: Engraving up to 400 mm/s, cutting up to 150 mm/s.

-

Safety Features: Built-in dust extraction and safety interlocks.

-

Glowforge Laser Engraver:

- Power Output: 40W CO2 laser.

- Bed Size: 9.75″ x 8″.

- Speeds: Engraving up to 350 mm/s, cutting up to 120 mm/s.

- Features: Smart Autofocus and Wi-Fi connectivity.

Considerations:

- Power and Capacity: The LaserHawk is better for thicker plastics and industrial use, while the Glowforge suits smaller projects.

- User Experience: Glowforge is more user-friendly with intuitive software; LaserHawk offers advanced controls.

- Material Compatibility: Both work with various plastics, wood, fabric, etc.

Best Practices:

- Clean materials before engraving.

- Perform test runs.

- Ensure proper ventilation and safety precautions.

Conclusion:

Choose based on project size and material needs. The LaserHawk is ideal for industrial or large-scale projects, while the Glowforge is perfect for smaller, more portable uses. Both are versatile tools for bringing creative ideas to life with precision.

Richard Chen –

Laser engraver delivers exceptional precision & detail. User-friendly software & smooth operation. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Juan Wagner –

Laser engraver delivers exceptional detail and precision. The intuitive software and smooth operation make it a breeze to use. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Sofia Mueller –

As a laser engraver user, I give this machine 5 stars. The engraving effects are crisp, precise. The operation is smooth, software intuitive. Fast speeds boost productivity. Solid build, reliable performance.

Ingrid Svensson (verified owner) –

**Performance & User Experience Review:**

The 40W CO2 laser excels on wood (detailed 600dpi engravings on birch), acrylic (smooth, polished edges), and leather (variable depth control). However, 6mm+ materials require slower speeds, affecting throughput. The intuitive drag-drop software simplifies vector/raster workflows, though offline functionality is limited. Autofocus and air-assist boost precision, but alignment jigs for multi-pass projects would enhance usability. At $2,499, it’s a robust mid-range option for artisans/small businesses, though maintenance costs (e.g., lens replacements) add up. Perfect for custom signage, intricate art, and leather goods.

Gabriella Han (verified owner) –

**Laser Engraver Review: A Craft Store Owner’s Experience**

**Specific Project Experience:**

I primarily used the laser engraver for personalized business gifts, such as custom acrylic awards and engraved wooden boxes. Wood behaved well with smooth engravings, while acrylic created a frosted finish. The challenge was achieving consistent depth across materials; test runs helped adjust settings effectively.

**Technical Performance:**

The engraver excels in power and precision, handling detailed designs effortlessly. The user-friendly software allows quick edits, and the air assist feature efficiently managed smoke during engravings.

**Business/Creative Impact:**

This tool revolutionized my workflow, enabling quick material switches and reducing costs. Customer feedback was overwhelmingly positive, appreciating the high-quality customization. The ROI is evident with reduced outsourcing needs and enhanced customer satisfaction.

**Comparison & Value:**

Compared to manual engravers or vinyl cutters, this laser is faster and more precise. Its cost-effectiveness stems from lower material waste and increased production efficiency. Time savings allow handling more projects daily, boosting productivity significantly.

This laser engraver has been a transformative addition, offering versatility and efficiency that have elevated my craft store’s offerings and customer satisfaction.

Jin Lee –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. 🌟🌟🌟🌟🌟”