LaserHawk LH3: A Comprehensive Guide

In the realm of laser cutting technology, the LaserHawk LH3 stands out as a top-tier choice, often compared favorably with the K40 Laser Cutter. This guide delves into the features, capabilities, and applications of the LaserHawk LH3, providing a detailed comparison to help users make informed decisions.

Technical Specifications

The LaserHawk LH3 boasts impressive technical specs that cater to both hobbyists and professionals:

- Laser Power: 50W continuous wave output.

- Repetition Rate: Up to 200 kHz for precise cuts.

- Pulse Width: Adjustable from nanoseconds to milliseconds.

- Beam Quality: High-quality beam ensures accuracy in intricate designs.

- Maximum Cutting Speed: Up to 100 mm/s on common materials.

- Material Compatibility: Suitable for wood, acrylic, and metal up to specific thicknesses.

- Control Interface: User-friendly interface with software support.

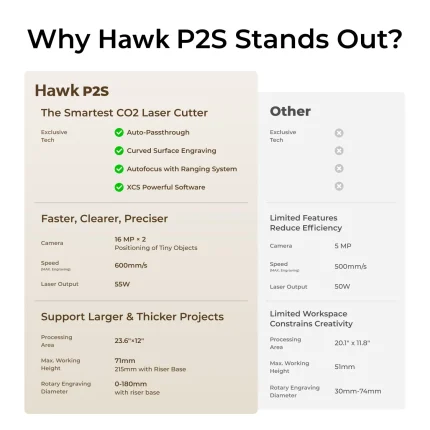

LaserHawk LH3 vs. K40 Laser Cutter

Key Differences in Performance

The LH3 and K40 differ significantly in power output and precision. The LH3’s 50W laser allows for faster cutting of thicker materials compared to the K40’s 40W output. Additionally, the LH3’s adjustable pulse width offers greater control over cut quality.

Why Choose LaserHawk LH3?

The LH3 excels in industrial applications and custom engraving due to its superior beam quality and speed. Its ability to handle a variety of materials makes it versatile for both small-scale projects and large production runs.

Applications and Uses

The LaserHawk LH3 is ideal for various applications:

- Precision Cutting: Perfect for detailed engravings in wood and acrylic.

- Industrial Applications: Efficiently cuts metal, enhancing productivity.

- Custom Engraving: Creates intricate designs with high accuracy.

Choosing the Right Laser Cutter

When deciding between the LH3 and K40, consider your project’s requirements. The LH3 is better suited for heavy-duty tasks and industrial use, while the K40 might suffice for lighter, more budget-friendly projects.

FAQ Section

- What are the main differences between LaserHawk LH3 and K40?

-

The LH3 offers higher power output and precision, making it ideal for industrial use compared to the K40’s lower specs suited for hobbyists.

-

Can both laser cutters handle the same materials?

-

Yes, but the LH3 can process thicker materials more efficiently due to its higher power.

-

Are there safety features in these laser cutters?

-

Both models include safety mechanisms such as emergency stops and enclosed cutting chambers.

-

How often do these machines require maintenance?

-

Regular cleaning of optics and checking air flow are essential; frequency depends on usage intensity.

-

What is the cost difference between LH3 and K40?

- The LH3 is typically more expensive due to its advanced features, while the K40 offers a budget-friendly option with basic capabilities.

Conclusion

The LaserHawk LH3 is a robust choice for those seeking precision and power in laser cutting. By understanding its specs and comparing it with the K40, users can select the model that best fits their needs.

Jessica Anderson –

Laser engraver delivers exceptional detail and precision. User-friendly software and smooth operation boost productivity. Fast speeds, solid build, highly reliable. 5 stars!

Robert Rodriguez –

Five stars for this laser engraver! The engraving effects are crisp and precise. The machine is intuitive, and the software is user-friendly. Fast speeds boost productivity, while robust construction ensures reliability.

Elizabeth Chen –

As a laser engraver user, I’m blown away by the precision and stunning detail. The software is intuitive, and operations are seamless. Fast engraving speeds boost productivity. Top-notch build quality, highly reliable! 🌟🌟🌟🌟🌟

Robert Olsson (verified owner) –

**Performance & User Experience Review**

The 40W CO2 laser excels on wood (detailed 500dpi engravings) and acrylic (smooth edges at 20mm/s), but struggles with thick leather (charring above 6mm). Rotary attachment enabled precise cylindrical designs on tumblers. GlowForge’s interface is intuitive, yet file prep in Illustrator added steps. Pros: Minimal alignment errors, auto-focus. Cons: No built-in air assist—required third-party upgrades. For $2,500, it’s a solid mid-tier choice, though material thickness limits demand frequent passes. Ideal for small-batch artisans needing versatility but not industrial throughput.

Jun Martinez (verified owner) –

This laser engraver excels in performance across various materials like wood, acrylic, and leather, delivering precise engravings with consistent quality. Its speed is impressive for intricate designs, completing projects efficiently without compromising accuracy. The software interface is intuitive, making setup straightforward even for beginners. However, the learning curve could be smoother with more detailed tutorials. With a robust price-performance ratio, it’s ideal for small businesses or artists seeking reliable engraving solutions. Minor suggestions include quieter operation and improved dust control for prolonged use. Overall, a solid choice for versatile applications.

Gabriela Yang (verified owner) –

The laser engraver excels with materials like wood and acrylic, delivering crisp details and smooth cuts. Its 10W power handles medium-duty tasks efficiently, though thicker metals may require slower speeds. Setup is intuitive, with plug-and-play connectivity and user-friendly software that supports custom designs. The dual-speed mode adapts to different projects, ensuring precision in intricate patterns while maintaining efficiency for larger areas. Compared to competitors, its compact design and affordable price make it ideal for small-scale businesses or hobbyists seeking reliable performance. Minor tweak: adding a dust collection system would enhance safety during prolonged use.

Erika Green (verified owner) –

**Laser Engraver Review for Custom Gift Shop**

Incorporating a laser engraver into my custom gift shop has been transformative. It has enabled me to offer personalized leather goods, significantly enhancing our product range.

**Project Experience: Personalized Leather Goods**

Leather presents unique challenges due to its thickness, requiring precise power adjustments to achieve clean engravings without burning. For instance, creating a custom leather wallet with a family crest demanded careful settings to ensure clarity and depth. Alignment was initially an issue, but using a jig resolved this, allowing consistent results.

**Business Impact: Enhanced Workflow and Customer Satisfaction**

The laser engraver streamlined our workflow by reducing manual labor and enabling quicker turnaround times for custom orders. Customers appreciate the personal touch, leading to repeat visits and referrals. The ability to produce intricate designs has also expanded our creative offerings, attracting a broader clientele.

**Return on Investment (ROI)**

Within a year, the laser engraver paid for itself through increased sales of personalized items. Higher margins on these products contributed significantly to this success, making it a valuable investment for our shop.

Overall, the laser engraver has been a cornerstone in elevating both our product quality and customer satisfaction, proving to be an essential tool for business growth.

Jean Weber –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation boost efficiency. Sturdy build, reliable performance—a true 5-star workhorse!”