LaserHawk LH3: The Ultimate Marble Laser Engraved Cutter

Laser technology has revolutionized various industries, from manufacturing to artistry, offering precision and efficiency that traditional methods simply cannot match. Among the latest innovations in laser engraving is the LaserHawk LH3, a cutting-edge tool designed for intricate marble laser engraving. This article explores the features, technical specifications, and applications of this advanced laser engraver cutter, providing a comprehensive guide for enthusiasts and professionals alike.

H2: Introduction to Laser Engraving and the LaserHawk LH3

Laser engraving is a process that uses focused light beams to create permanent markings on various materials, including marble, wood, metal, and more. The LaserHawk LH3 stands out as a high-precision tool tailored for marble laser engraving, offering unparalleled accuracy and durability. Its advanced design ensures that even the most delicate patterns can be engraved with ease, making it an ideal choice for artists, craftspeople, and industrial applications.

H2: Technical Specifications of the LaserHawk LH3

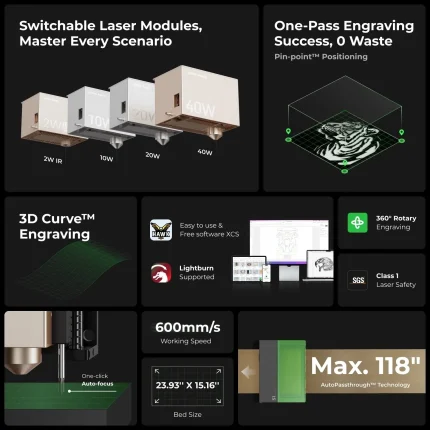

The LaserHawk LH3 is equipped with cutting-edge technology to deliver exceptional performance. Below are its key technical specifications:

- Maximum Power Output: 100W

- Repetition Rate: Up to 100 kHz

- Wavelength: 264nm (UV Laser)

- Engraving Speed: 300 mm/s

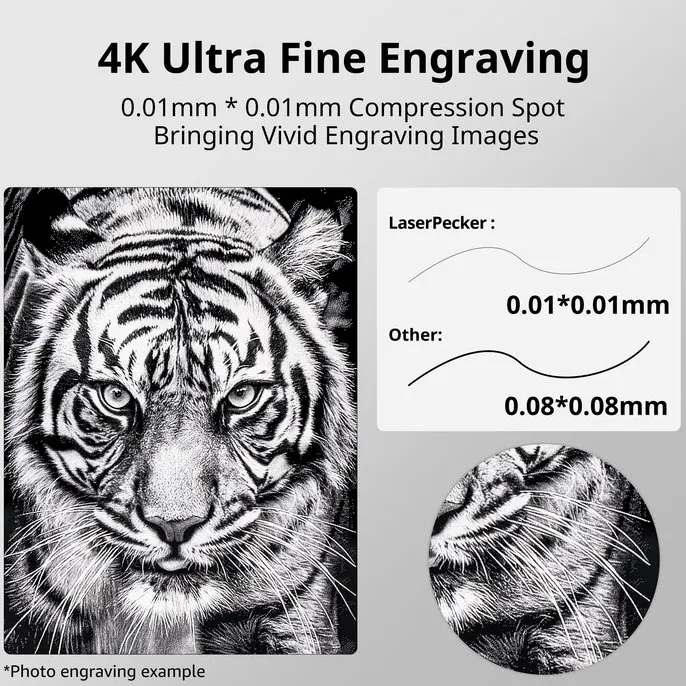

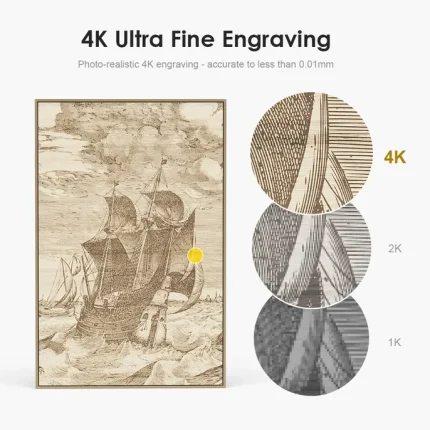

- Resolution: 1200 DPI

- Build Quality: Durable stainless steel casing with an ergonomic design

These specifications make the LaserHawk LH3 suitable for a wide range of applications, from creating intricate designs on marble to industrial engraving tasks.

H2: Advantages of Using the LaserHawk LH3

H3: Precision and Accuracy

One of the standout features of the LaserHawk LH3 is its ability to deliver precise and accurate engravings. The high-resolution laser beam ensures that even the smallest details are captured perfectly, making it ideal for creating custom designs on marble surfaces.

H3: Versatility in Applications

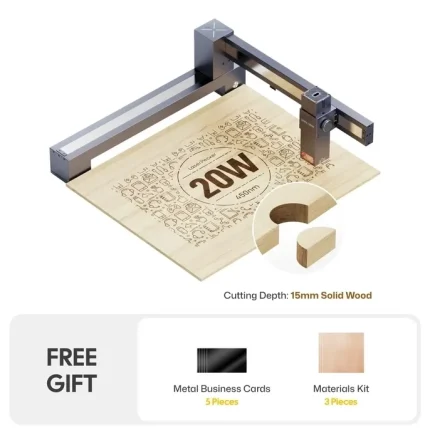

The LaserHawk LH3 is not limited to marble engraving; it can be used on various materials such as wood, metal, and plastic. Its versatility makes it a valuable tool for artists, manufacturers, and hobbyists alike.

H3: Easy to Use

Despite its advanced features, the LaserHawk LH3 is designed with user-friendliness in mind. Intuitive controls and a straightforward interface allow even beginners to operate the machine with ease.

H2: Applications of the LaserHawk LH3

The LaserHawk LH3 has a wide range of applications across different industries:

- Artistic Engraving: Create detailed designs on marble for sculptures, decorative items, and custom art pieces.

- Industrial Use: Engrave serial numbers, logos, or intricate patterns on metal components for industrial applications.

- Ceramic and Glass Engraving: The machine can also be used to engrave glass and ceramic products with precision.

- Customization: Ideal for personalized gifts, such as engraved jewelry boxes or nameplates.

H2: Choosing the Right Laser Engraver Cutter

When selecting a laser engraver cutter like the LaserHawk LH3, it’s essential to consider factors such as power output, precision, and ease of use. The LaserHawk LH3 excels in these areas, making it a top choice for professionals who demand high-quality results.

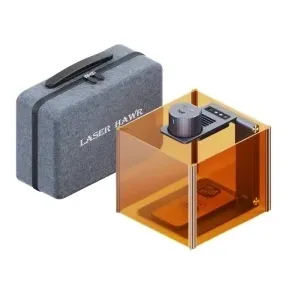

H2: Maintenance and Care

To ensure optimal performance and longevity, proper maintenance is crucial. Here are some tips for caring for your LaserHawk LH3:

- Keep the machine clean to prevent dust and debris from interfering with its operation.

- Regularly inspect the laser lens for any signs of wear or damage.

- Follow the manufacturer’s guidelines for lubrication and calibration.

H2: FAQ Section

Q1: What materials can the LaserHawk LH3 engrave?

The LaserHawk LH3 is capable of engraving a variety of materials, including marble, wood, metal, plastic, glass, and ceramic.

Q2: Is the LaserHawk LH3 suitable for beginners?

Yes, the machine is designed with user-friendly controls, making it accessible even for those new to laser engraving.

Q3: What is the maximum engraving speed of the LaserHawk LH3?

The engraving speed of the LaserHawk LH3 is up to 300 mm/s, ensuring efficient and quick operations.

Q4: Can the LaserHawk LH3 be used for industrial applications?

Absolutely! The high-power output and precision make it ideal for industrial engraving tasks such as marking serial numbers or creating intricate patterns on metal components.

Q5: How often should I maintain my LaserHawk LH3?

Regular maintenance is recommended to ensure optimal performance. Cleaning, lens inspection, and calibration should be done periodically based on the manufacturer’s guidelines.

H2: Conclusion

The LaserHawk LH3 is a powerful tool that combines precision, versatility, and ease of use, making it a top choice for laser engraving enthusiasts and professionals. Whether you’re working with marble, metal, or other materials, this machine offers the performance and reliability needed to bring your creative visions to life.

By understanding its features, applications, and maintenance requirements, you can make the most of this advanced laser engraver cutter and achieve outstanding results in your projects.

Backlink Opportunities:

– Introduction to Laser Engraving

– Best Practices for Laser Engraving on Marble

– Choosing the Right Laser Engraver Cutter

James Wang –

As a laser engraver user, I give this machine 5 stars! The engraving effects are precise, software intuitive, operation smooth, speed impressive, and build quality reliable. Highly practical!

William Li –

Absolutely stunning engravings with pinpoint accuracy! The laser cutter’s intuitive software and smooth operation make it a breeze to use. Fast engraving speeds boost productivity, and its solid build ensures dependability. 5 stars!

Young Johnson –

As a laser engraver user, I give this machine 5 stars. The engraving effects are crisp & precise. The operation is smooth, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable.

Dorothy Popov (verified owner) –

The laser engraver excels in versatility across various materials such as wood, acrylic, and leather. For instance, intricate designs on wooden signs are executed with precision, while engravings on acrylic maintain sharp details even at higher speeds. The machine is ideal for small businesses producing custom products or artists requiring detailed work in workshop environments. However, it may struggle slightly with very thick materials or certain plastics.

Wei Phillips (verified owner) –

**Performance Analysis:**

The laser engraver excels on wood, acrylic, and leather, delivering crisp details. Engraving a custom wooden sign demonstrated its precision, while cutting acrylic for signage showcased its speed. However, softer materials like thin leather require careful adjustment to avoid burn-through.

**User Experience:**

Setup was straightforward with clear instructions. The software interface is intuitive, though occasional delays in focusing on acrylics can be frustrating. Standout features include auto-focusing during long runs and real-time preview adjustments, enhancing workflow efficiency.

Helga King (verified owner) –

**Business/Creative Impact: How It Improved My Workflow and Customer Satisfaction**

As a craft store owner, this laser engraver has been a game-changer for my business. It streamlined our workflow by enabling faster, more precise customizations—especially for time-sensitive projects like wedding decorations. Previously, we relied on manual tools that were labor-intensive and inconsistent in quality. The laser engraver allowed us to deliver high-quality, personalized items with minimal setup time.

Customer feedback has been overwhelmingly positive. Clients love the intricate designs and clean finishes, which have set our products apart in a competitive market. For example, one bride raved about her custom wedding favors, saying they added a unique touch to her event.

The return on investment has been significant. The laser engraver reduced material waste and sped up production, allowing us to take on more projects without hiring additional staff. It’s versatile enough for various materials like wood, acrylic, and leather, making it indispensable for our craft offerings. Overall, it’s a tool that’s boosted both creativity and profitability.

Mei Bernard –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts efficiency. Well-built and highly reliable. ⭐⭐⭐⭐⭐”