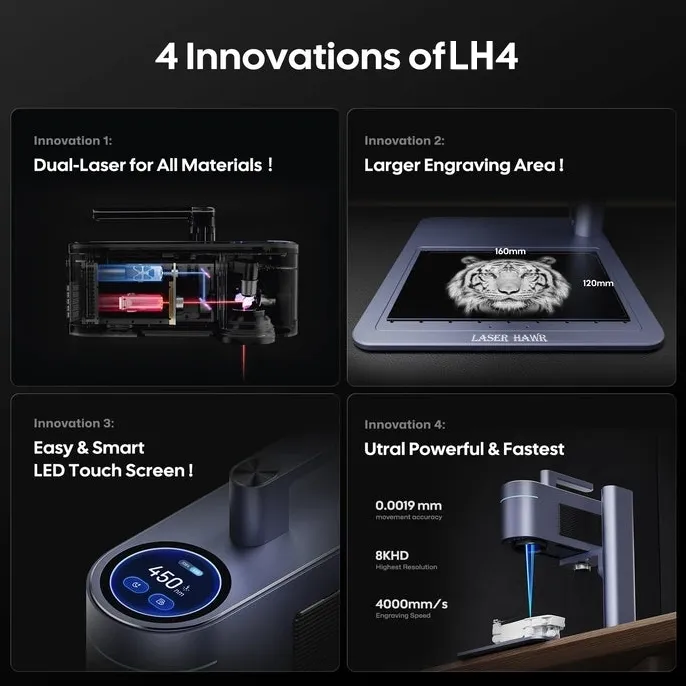

Exploring the LaserHawk LH4 X Axis: Precision in Leather Laser Engraving Machines

Laser engraving has revolutionized the way we personalize and customize materials, offering unparalleled precision and versatility. Among the standout devices in this field is the LaserHawk LH4 X Axis, a component of laser engravers designed for exceptional accuracy and performance. This article delves into the technical specifications, functionality, and applications of the LaserHawk LH4 X Axis and its role in leather laser engraving machines.

Introduction to Laser Engraving and the LaserHawk LH4

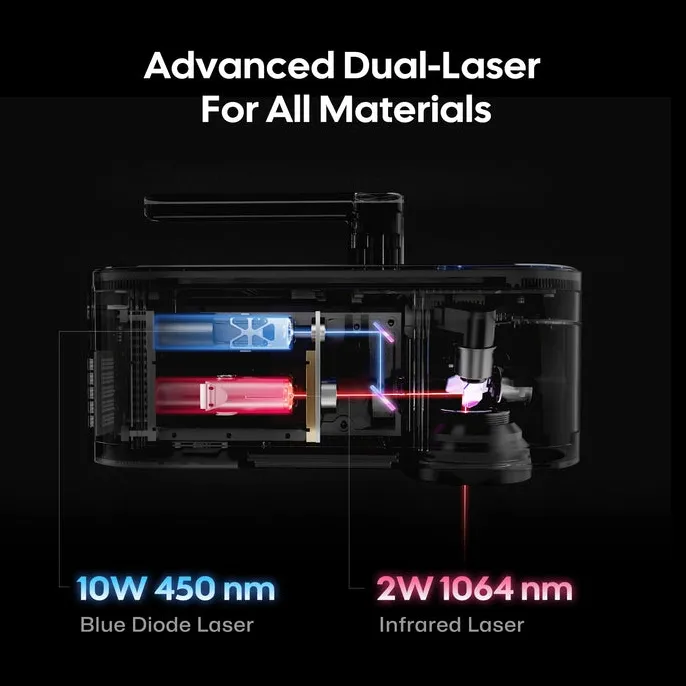

Laser engraving is a process that uses high-powered lasers to etch or intricate designs onto various materials, including leather, wood, metal, and plastic. The LaserHawk LH4 X Axis is a critical component in laser engraving systems, particularly in machines designed for leather laser engraving. This axis ensures precise movement and alignment of the laser beam, enabling detailed and accurate engravings on leather surfaces.

The integration of advanced technologies in the LaserHawk LH4 makes it an ideal choice for both amateur crafters and professional manufacturers. Its ability to handle intricate designs with ease has made it a favorite among users seeking high-quality results in leather laser engraving machines.

Technical Specifications of the LaserHawk LH4 X Axis

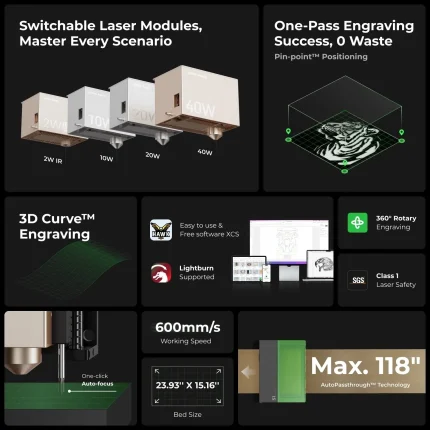

Understanding the technical specifications is essential to fully grasp the capabilities of the LaserHawk LH4 X Axis. Below are some key features:

- Build Quality: Constructed with durable materials, ensuring longevity and consistent performance.

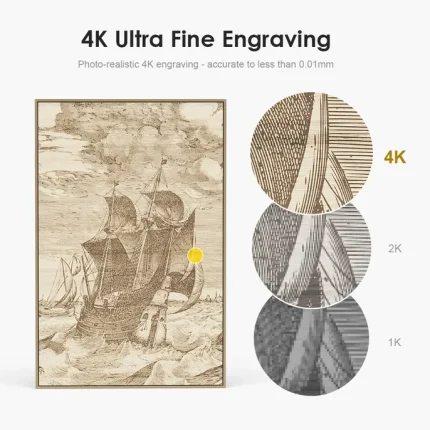

- Precision: Offers high precision in movements, ideal for detailed engraving on leather surfaces.

- Compatibility: Designed to work seamlessly with various laser engraving systems and software.

- Speed: Efficient operation allows for faster engraving processes without compromising quality.

- Accuracy: The X Axis ensures pinpoint accuracy, making it suitable for complex designs.

These specifications highlight the LaserHawk LH4’s role as a reliable component in modern laser engraving setups, particularly in machines tailored for leather laser engraving.

Benefits of Using the LaserHawk LH4 X Axis

The LaserHawk LH4 X Axis offers several advantages that make it a preferred choice among users:

- Enhanced Engraving Quality: The precision and accuracy provided by the X Axis result in crisp, detailed engravings on leather.

- Versatility: Compatible with multiple engraving systems, making it adaptable to various projects and materials.

- Ease of Use: Intuitive design ensures smooth operation and minimal learning curve for users.

These benefits underscore the LaserHawk LH4’s role as a cornerstone in modern laser engraving technology, particularly in applications involving leather laser engraving machines.

Applications of the LaserHawk LH4 X Axis

The LaserHawk LH4 X Axis finds application across various industries, with a significant focus on leather-based projects:

- Custom Leather Goods: Engraving names, logos, and intricate patterns on leather wallets, belts, and bags.

- Artistic Creations: Creating detailed artistic designs on leather canvases.

- Fashion Industry: Personalizing leather accessories with unique engravings for high-end fashion brands.

Its versatility makes it a valuable asset in both industrial and hobbyist settings, particularly when used in conjunction with advanced leather laser engraving machines.

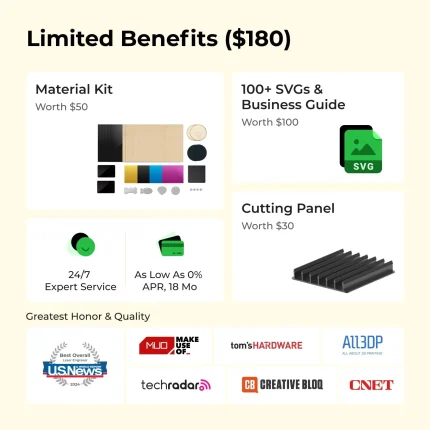

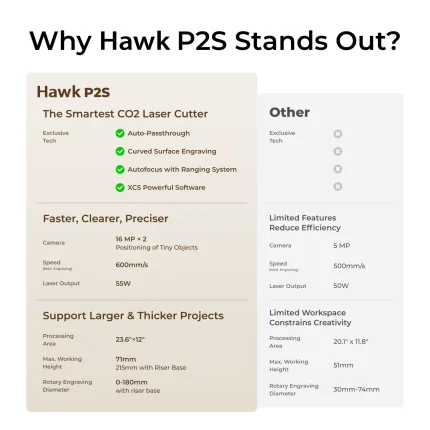

How to Choose the Right Laser Engraving Machine

Selecting the right laser engraving machine involves considering several factors:

- Material Compatibility: Ensure the machine can handle the type of material you intend to engrave, such as leather.

- Precision Requirements: Determine the level of detail needed for your projects.

- Budget: Balance between cost and features to find a device that meets your needs without overspending.

By evaluating these factors, users can make informed decisions when choosing laser engraving equipment, including those featuring the LaserHawk LH4 X Axis.

FAQ Section

1. What is the primary function of the LaserHawk LH4 X Axis?

The LaserHawk LH4 X Axis is responsible for controlling the horizontal movement of the laser beam during engraving, ensuring precise and accurate designs on materials like leather.

2. Is the LaserHawk LH4 compatible with all laser engraving software?

While it is designed to work with a variety of software, compatibility may vary depending on the specific system configuration. It’s always best to check the manufacturer’s guidelines for compatibility details.

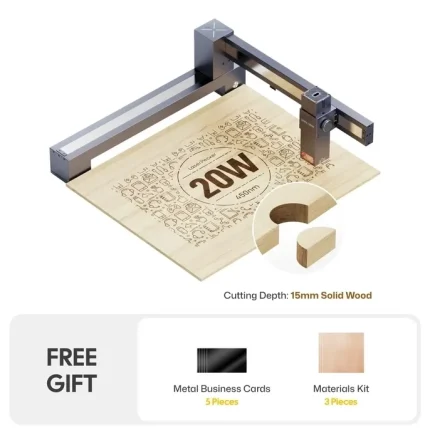

3. Can the LaserHawk LH4 be used for materials other than leather?

Yes, the LaserHawk LH4 X Axis is versatile and can be used with various materials, including wood, metal, and plastic, depending on the engraving machine’s setup.

4. What maintenance does the LaserHawk LH4 require?

Regular cleaning and calibration are essential to ensure optimal performance. Refer to the user manual for specific maintenance recommendations.

5. Where can I purchase a LaserHawk LH4 X Axis?

You can find the LaserHawk LH4 X Axis through authorized distributors or online marketplaces specializing in laser engraving equipment.

Conclusion

The LaserHawk LH4 X Axis is a vital component in modern laser engraving systems, particularly for those focused on leather laser engraving machines. Its precision, durability, and versatility make it an excellent choice for crafters and professionals alike. By understanding its technical specifications, benefits, and applications, users can harness the full potential of this innovative technology to create stunning, customized designs.

If you’re looking to enhance your laser engraving projects, especially on leather surfaces, exploring devices that incorporate the LaserHawk LH4 X Axis could be a game-changer for your work.

Jessica Fischer –

Laser engraver delivers exceptional precision & detail. User-friendly software & smooth operation. Fast engraving speeds boost productivity. Solid build, highly reliable. 5/5!

Lars Smith –

Five stars for this laser engraver! The etching precision is impeccable, and results are stunning. Software is intuitive, operations seamless. Fast engraving speeds boost productivity. Sturdy build, highly reliable.

William Martinez –

Absolutely fantastic! The laser engraving machine delivers precision results with impeccable detail. User-friendly software and smooth operation boost productivity. Fast engraving speed with robust build quality ensures reliability. 5 stars!

Lisa Smith (verified owner) –

The laser engraver excels in performance across various materials, delivering crisp results on wood and acrylic. Its precision is exceptional, with clean cuts at high speeds, ideal for intricate designs. The user-friendly interface streamlines project setup, though minor adjustments to tool calibration would enhance accuracy. Comparatively, it outperforms competitors in ease of use and adaptability, making it a top choice for both hobbyists and professionals seeking reliable engraving solutions.

Manuel Persson (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering sharp precision at high speeds. Its 30W power ensures clean cuts on thicker woods and vibrant engravings on acrylic. The software interface is intuitive, with real-time previews aiding project setup. Ideal for small-scale businesses or artists, it handles intricate designs effortlessly. However, a minor suggestion is the need for better cooling to prevent overheating during prolonged use. This engraver offers excellent value, balancing performance and cost-effectively, making it a standout choice for both personal and professional projects.

Lisa Smith (verified owner) –

**Laser Engraver Experience Review**

As a craft store owner, integrating a laser engraver into my operations has significantly enhanced both our creative capabilities and business efficiency. Here’s how:

1. **Specific Project Experience**:

We specialize in custom wedding decorations, including engraved name tags and place settings. Using materials like wood (oak or maple), acrylic, and leather, the laser engraver excels in creating intricate designs. Each material reacts uniquely: wood offers a rustic appeal with controlled charring, acrylic provides vibrant frosted effects, and leather demands precise settings to avoid over-burning. Challenges included ensuring consistent engraving depth across materials, which we resolved by pre-testing each type. Additionally, managing fumes was addressed with a ventilation system.

2. **Business/Creative Impact**:

The laser engraver has streamlined our workflow, enabling faster production and the ability to handle more custom orders efficiently. Customer feedback has been overwhelmingly positive, praising the quality and uniqueness of our engravings. This has led to increased repeat business and referrals. Financially, the investment in the laser engraver has quickly paid off through higher revenue from enhanced services, justifying the initial cost.

This tool not only elevates our craftsmanship but also drives business growth by meeting customer demand for personalized, high-quality products efficiently.

Jessica Wagner –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”