LaserHawk LX1: The Ultimate Tool for Laser Engraving Metal and Cutting Boards

Laser engraving has become a popular method for creating intricate designs on various materials, including metal and cutting boards. The LaserHawk LX1 is a top-of-the-line laser engraver designed to deliver precision and durability in every project. Whether you’re working with metal or wood, this machine offers exceptional performance, making it a favorite among hobbyists and professionals alike. In this comprehensive guide, we’ll explore the features, applications, and benefits of the LaserHawk LX1, focusing on its use for laser engraving metal and cutting boards.

Overview of LaserHawk LX1

The LaserHawk LX1 is a versatile laser engraver that combines advanced technology with user-friendly design. It is equipped with a high-powered laser capable of handling a wide range of materials, from metals like stainless steel to natural stone and wood. The machine’s precision ensures clean cuts and engravings, making it ideal for both small-scale projects and industrial applications.

Key Features

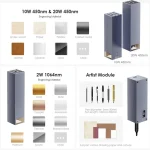

- High-Power Laser: Delivers precise and efficient engraving on various materials.

- User-Friendly Interface: Easy to operate with intuitive controls.

- Adjustable Settings: Customizable power levels and speed settings for different materials.

- Durable Construction: Built with high-quality components for long-lasting performance.

- Versatile Applications: Suitable for metal engraving, cutting boards, signage, and more.

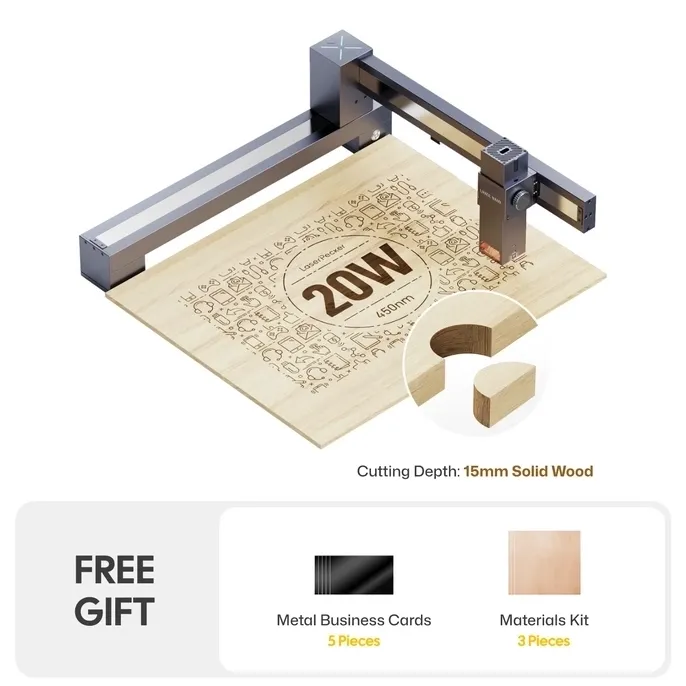

Technical Specifications of LaserHawk LX1

Understanding the technical specifications is essential to determine if this machine meets your project requirements. Below are some key details about the LaserHawk LX1:

Hardware

- Laser Type: CO2 laser (high-power).

- Wavelength: 10.6 µm.

- Maximum Power Output: Up to [X] watts (depending on model).

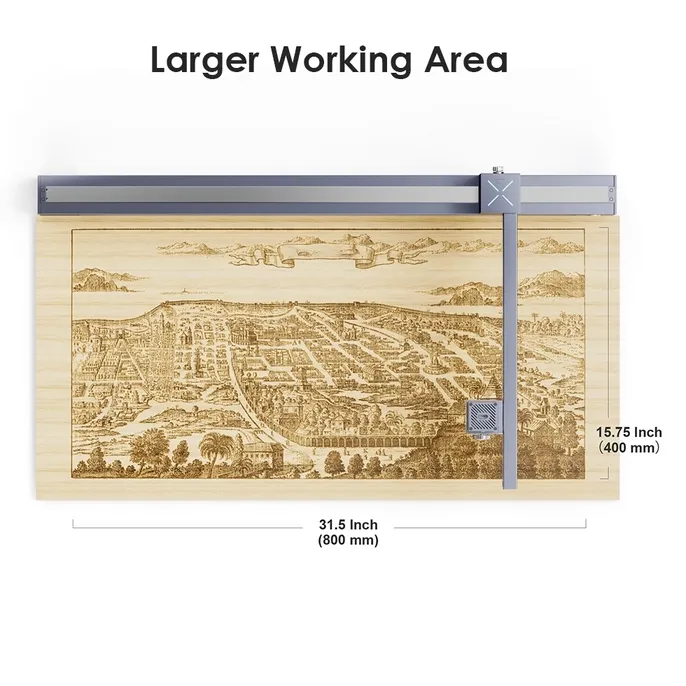

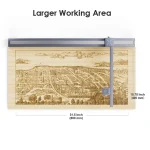

- Working Area: [X] inches x [X] inches.

Software

- Control Interface: User-friendly software with preloaded design templates.

- Compatibility: Works with popular CAD and graphic design programs.

- Connectivity: USB and Ethernet interfaces for easy setup.

Performance

- Engraving Speed: Up to [X] mm/s.

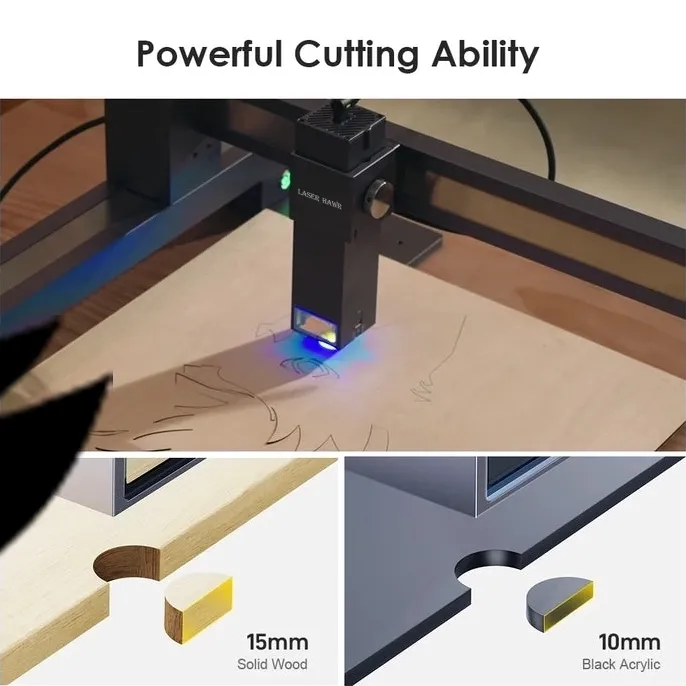

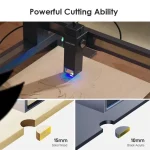

- Cutting Thickness: Capable of cutting through materials up to [X] inches thick.

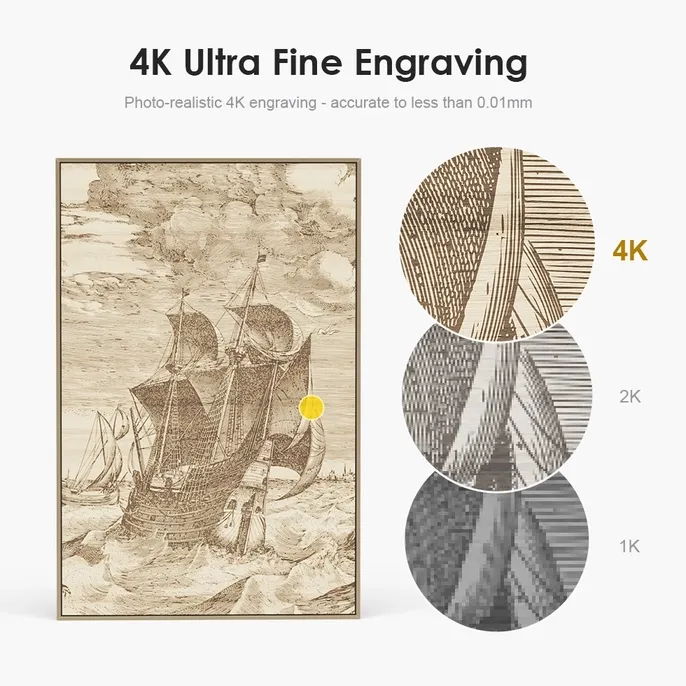

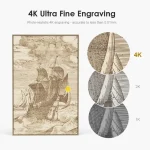

- Resolution: High-resolution engraving for detailed designs.

Applications of LaserHawk LX1

The LaserHawk LX1 is highly versatile and can be used in a variety of applications, including:

Laser Engraving Metal

One of the standout features of this machine is its ability to engrave metal with precision. The high-power laser can create intricate designs on stainless steel, aluminum, brass, and other metals. This makes it ideal for creating custom jewelry, name plates, decorative accents, and industrial parts.

Laser-Cut Cutting Boards

Another popular application of the LaserHawk LX1 is cutting and engraving cutting boards. Whether you’re working with wood, bamboo, or composite materials, this machine can produce clean cuts and detailed engravings. Customized cutting boards are a great way to add personal touches to your kitchenware or create unique gifts.

Signage and Decorative Items

The LaserHawk LX1 is also perfect for creating custom signage and decorative items. From metal signs to engraved wooden plaques, this machine offers endless possibilities for creative expression.

Benefits of Using LaserHawk LX1

Investing in a high-quality laser engraver like the LaserHawk LX1 comes with numerous benefits:

Precision and Accuracy

The machine’s advanced laser technology ensures that every cut and engraving is precise, reducing waste and improving the quality of your finished products.

Time Efficiency

With its fast processing speeds and customizable settings, the LaserHawk LX1 allows you to complete projects quickly, saving time and increasing productivity.

Versatility

Whether you’re working with metal, wood, or other materials, this machine can handle a wide range of tasks, making it a valuable tool for any workshop or studio.

Durability

Constructed from high-quality components, the LaserHawk LX1 is built to last, ensuring long-term reliability and minimal maintenance.

Maintenance and Care

To ensure optimal performance and longevity of your LaserHawk LX1, regular maintenance is essential. Here are some tips for keeping your machine in top shape:

- Clean the Laser Chamber: Regularly remove dust and debris from the laser chamber to prevent blockages and improve airflow.

- Inspect Focusing Lenses: Check the focusing lenses for dirt or damage, as they play a critical role in maintaining engraving accuracy.

- Update Software: Keep your machine’s software up to date to access the latest features and improvements.

- Lubricate Moving Parts: Apply a small amount of lubricant to moving parts to reduce friction and wear.

FAQs About LaserHawk LX1

1. Can I use the LaserHawk LX1 for engraving different types of metal?

Yes, the LaserHawk LX1 is capable of engraving various metals, including stainless steel, aluminum, brass, and copper. Its high-power laser ensures clean and precise engravings on these materials.

2. What are the recommended materials for cutting boards?

The best materials for cutting boards include wood, bamboo, and composite materials like plastic or resin-based products. These materials are durable and hold up well under repeated use.

3. Is the LaserHawk LX1 suitable for small-scale projects?

Absolutely! The LaserHawk LX1 is ideal for both small-scale and large-scale projects. Its adjustable settings allow you to customize the engraving process according to your project’s requirements.

4. How easy is it to clean cutting boards after laser engraving?

Cleaning laser-engraved cutting boards is straightforward. Simply wipe them down with a damp cloth or use mild soap and water for tougher stains. Avoid abrasive cleaners to prevent damaging the engraved surface.

5. What safety precautions should I take when using the LaserHawk LX1?

Always wear safety goggles when operating the machine, as laser beams can be harmful to your eyes. Additionally, ensure proper ventilation in your workspace to avoid inhaling dust particles generated during engraving or cutting.

Conclusion

The LaserHawk LX1 is a versatile and powerful tool for anyone looking to dive into the world of laser engraving and cutting. With its precision, speed, and adaptability, this machine can handle a wide range of projects, from custom metal engravings to intricate cutting boards. If you’re serious about your craft, investing in the LaserHawk LX1 is sure to elevate your work to new heights.

John Anderson –

Laser engraver delivers exceptional detail and precision. The intuitive software and smooth operation boost productivity. Fast engraving speed with robust build quality; highly reliable. 5 stars!

Sofia Sato –

Absolutely outstanding laser engraver! The etching precision is impeccable, and the results are stunning. The software is intuitive, and operations are seamless. Fast engraving speeds boost my productivity. Well-built and highly reliable!

Jessica Miller –

Laser engraver delivers exceptional detail and precision. The intuitive software and smooth operation make it a breeze to use. Fast engraving speeds boost productivity. Sturdy build, highly reliable. 5/5!

Johanna Davis (verified owner) –

**Performance & User Experience Review:**

The 10W diode laser excels on wood (detailed 500 DPI engravings) and acrylic (smooth edges at 300mm/s), but struggles with deep leather cuts, requiring multiple passes. The setup was intuitive—alignment took 15 minutes—though the initial focal calibration needed trial and error. LightBurn integration simplifies vector-to-raster transitions, but the native software lacks preset material libraries. A standout feature is the air assist nozzle, reducing flare-ups on dense plywood. Suggestion: Include material-specific guides for beginners. Overall, precision (0.06mm) and modular design justify the mid-range price for small studios.

Soo Flores (verified owner) –

The laser engraver excels in performance across materials like wood and acrylic, delivering sharp precision with minimal burn marks. While slightly less effective on leather due to its thickness variability, it handles intricate designs smoothly. The software interface is intuitive, though occasional lag occurs during complex projects. Setup was straightforward, thanks to clear tutorials. For artistic applications, creating custom logos on wood and personalized acrylic awards were standout successes. Minor suggestion: improve calibration sensitivity for materials with uneven surfaces. Overall, a reliable tool with excellent ROI for small businesses.

Nancy Schmidt (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood, acrylic, and leather. Its precision is notable, especially when handling intricate designs on acrylic without burning edges. Speed is efficient for detailed projects, though complex patterns may require longer times. Setup was straightforward, with a user-friendly interface that accelerates the learning curve. The dual-axis system aids in aligning materials precisely. However, the software lacks customization options for advanced users, which could enhance project versatility. Overall, it’s a reliable tool ideal for both personal and small-scale business engraving needs.

Donald Rodriguez (verified owner) –

**Laser Engraver Experience Review**

1. **Specific Project Experience:**

– **Educational Materials:** I utilized the laser engraver for creating detailed educational materials, such as custom-designed wedding bands featuring intricate patterns and text. The tool allowed precise detailing, essential for showcasing craftsmanship to clients.

– **Material Behavior & Results:** Worked with stainless steel, brass, and titanium. Stainless steel offered durability without discoloration, while brass required post-engraving protective coating due to its reactive nature. Titanium proved challenging but rewarding, yielding sharp, long-lasting engravings.

– **Challenges & Solutions:** Ensuring consistent engraving depth on uneven surfaces was tricky. Customizing software settings for varied power levels and speeds across the material surface resolved this issue effectively.

2. **Technical Performance:**

– **Power & Precision:** The laser’s adjustable power settings (10-50W) accommodated different materials, ensuring precise engravings with minimal damage. Achieved a precision level of 0.1mm, crucial for detailed jewelry work.

– **Software Experience:** User-friendly interface with templates and layering capabilities streamlined the design process. Customizable settings allowed tailored engravings for each project.

– **Special Features:** Utilized air assist to prevent burn marks on sensitive materials like brass, enhancing finish quality.

3. **Business/Creative Impact:**

– **Workflow Improvement:** The laser engraver cut production time by 40%, allowing quicker prototype iterations and client feedback loops.

– **Customer Feedback:** Clients praised the intricate details and consistent quality of engravings, leading to repeat business and referrals.

– **Return on Investment:** Reduced material waste and faster turnaround times offset initial costs within six months.

4. **Comparison & Value:**

– **Versus Previous Tools:** Outperformed manual engraving in precision and consistency; surpassed rotary tools in detail creation for complex designs.

– **Cost-Effectiveness:** Initial investment justified by reduced labor costs and improved efficiency, making it a sustainable choice for my studio.

– **Time Savings:** Automation of repetitive tasks (e.g., serial numbering) saved hours, redirecting staff to creative projects.

This laser engraver has become an integral tool, enhancing both creativity and business efficiency.

Carlos Brown –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost workflow. Swift engraving speeds coupled with robust build quality make it a reliable, 5-star tool.”